Elevators, Lifts or Hoists, machines for raising or lowering loads, whether of people or material, from one level to another. They are operated by steam, hydraulic or electric power, or, when small and light, by hand. Their construction varies with the magnitude of the work to be performed and the character of the motive power. In private houses, where only small weights, as coal, food, &c., have to be transferred from one floor to another, they usually consist simply of a small counter-balanced platform suspended from the roof or an upper floor by a tackle, the running part of which hangs from top to bottom and can be reached and operated at any level. In buildings where great weights and numbers of people have to be lifted, or a high speed of elevation is demanded, some form of motor is necessary. This is usually, directly or indirectly, a steam-engine or occasionally a gas-engine; sometimes a water-pressure engine is adopted, and it is becoming more and more common to employ an electric motor deriving its energy from the general distribution of the city. Large establishments, hotels or business houses, commonly have their own source of energy, an electric or other power “plant,” on the premises.

|

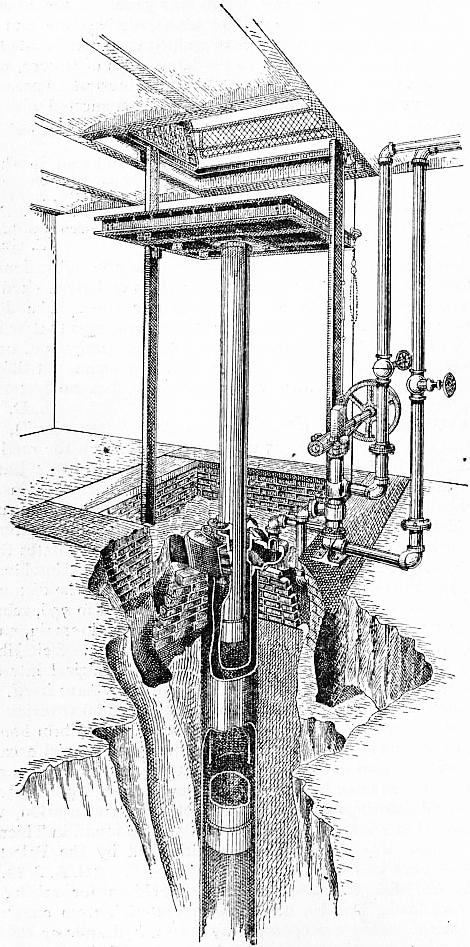

| Fig. 1.—The Plunger, or Direct Lift Hydraulic Engine. |

|

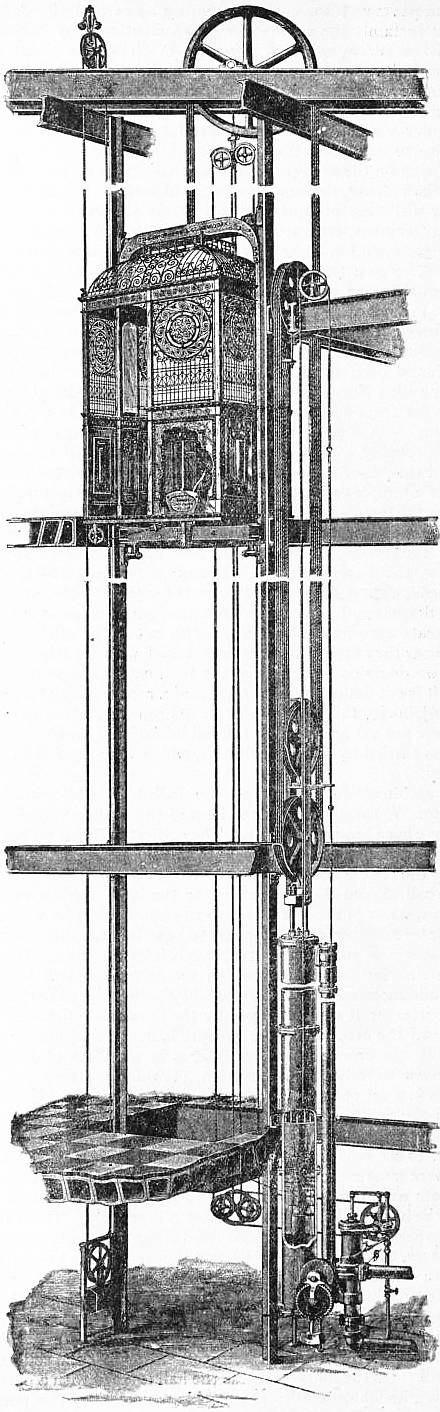

| Fig. 2.—The Otis Standard Hydraulic Passenger Lift, with Pilot Valve and Lever-operating Device. |

The hydraulic elevator is the simplest in construction of elevators proper, sometimes consisting merely of a long pipe set deeply in the ground under the cage and containing a correspondingly long plunger, which rises and falls Construction of elevators. as required and carries the elevator-cage on its upper end (fig. 1). The “stroke” is thus necessarily equal to the height traversed by the cage, with some surplus to keep the plunger steady within its guiding-pipe. The pipe or pump chamber has a length exceeding the maximum rise and fall of the plunger, and must be strong enough to sustain safely the heavy hydraulic pressures needed to raise plunger and cage with load. The power is usually supplied by a steam pump (occasionally by a hydraulic motor), which forces water into the chamber of the great pipe as the elevator rises, a waste-cock drawing off the liquid in the process of lowering the cage. A single handle within the cage generally serves to apply the pressure when raising, and to reduce it when lowering the load. The most common form of hydraulic elevator, for important work and under usual conditions of operation, as in cities, consists of a suspended cage, carried by a tackle, the running part of which is connected with a set of pulleys at each end of a frame (fig. 2). The rope is made fast at one end, and its intermediate part is carried round first one pulley at the farther end of the frame and then round another at the nearer end, and so on as often as is found advisable in the particular case. The two pulley shafts carrying these two sets of pulleys are made to traverse the frame in such a way as, by their separation, to haul in on the running part, or, by their approximation, to permit the weight of the cage to haul out the rope. By this alternate hauling and “rendering” of the rope the cage is raised and lowered. The use of a number of parallel and independent sets of pulleys and tackles assures safety in case of the breakage of any one, each being strong enough alone to hold the load. The movement of the pair of pulley shafts is effected by a water-pressure engine, actuating the plunger of a pump which is similar to that used in the preceding apparatus, but being relatively of short stroke and large diameter, is more satisfactory in design and construction as well as in operation. Electricity may be applied to elevators of this type by attaching the travelling sheaves to a nut in which works a screwed shaft driven by an electric motor. In other electric lifts the cables which support the cage are wound on a drum which is turned by a motor, the drum being connected to the motor-shaft either by a series of pinions or by a worm-gear. The drum may also be worked by a steam or gas engine. Where the traffic is not very heavy, a form of elevator that requires no attendant is convenient. In this any one wishing to use the lift has merely to press a button placed by the side of the lift-gate on the floor on which he happens to be standing, when the car will come to him; and having entered it he can cause it to travel to any floor he desires by pressing another button inside the car. The motive power in such cases may be either electric or hydraulic, but the control of the switches or valves that govern the action of the apparatus is electric.

The history of the elevator is chronologically extensive, but only since 1850 has rapid or important progress been effected. In that year George H. Fox & Co. built an elevator operated by the motion of a vertical screw, the nut on which carried the cage. This device was used in a number of instances, especially in hotels in the large cities, during the succeeding twenty years, and was then generally supplanted by the hydraulic lift of the kind already described as the plunger-lift. With the increased demand for power, speed, safety, convenience of manipulation, and comfort in operation, the inventive ability of the engineer developed the various systems more and more perfectly, and experience gradually showed to what service each type was best adapted and the best construction of each for its peculiar work. Whatever the class, the following are the essentials of design, Essentials of design, &c. construction and operation: the elevator must be safe, comfortable, speedy and convenient, must not be too expensive in either first cost or maintenance, and must be absolutely trustworthy. It must not be liable to fracture of any element of the hoisting gear that will permit either the fall of the cage or its projection by an overweighted balance upwards against the top of its shaft. It must be possible to stop it, whether in regular working or in emergency, or when accident occurs, with sufficient promptness, yet without endangering life or property, or even very seriously inconveniencing the passengers. Acceleration and retardation in starting and stopping must be smooth and easy, the stop must be capable of being made precisely where and when intended, and no danger must be incurred by the passengers from contact with running parts of the mechanism or with the walls and doors of the elevator shaft.

These requirements have been fully met in the later forms of elevator commonly employed for passenger service. Usual sizes range from loads of 1000 to 5000 ℔ with speeds of from 80 to 250 ft. a minute unloaded, and 75 to 200 ft. loaded, and a height of travel of from 50 to 200 ft. In some very tall buildings, as the Singer and Metropolitan buildings in New York, elevators have been installed having a maximum speed of 600 ft. a minute, with a rise of over 500 ft. Where electric motors are employed, their speed ranges from 600 and 700 revolutions per minute in the larger to 1000 and 1200 in the smaller sizes, corresponding to from 20 down to 4 or 5 h.p. Two or more counter-weights are employed, and from four to six suspension cables ensure as nearly as possible absolute safety. The electric elevators of the Central London railway are guaranteed to raise 17,000 ℔ 65 ft. in some of its shafts, in 30 secs. from start to stop. Over 100,000 ft. of 7⁄8 in. and 17,000 ft. of ¾ in. steel rope are required for its 24 shafts, and each rope can carry from 16 to 22 tons without breaking. The steel used in the cables, of which there are four to six for each car and counter-weight, has a tenacity of 85 to 90 tons per sq. in. of section of wire. The maximum pull on each set of rope is assumed to be not over 9500 ℔, the remainder of the load being taken by the counterbalance. Oil “dash-pots” or buffers, into which enter plungers attached to the bottom of the cage, prevent too sudden a stop in case of accident, and safety-clutches with friction adjustments of ample power and fully tested before use give ample insurance against a fall even if all the cables should yield at once—an almost inconceivable contingency. The efficiency, i.e. the ratio of work performed to power expended in the same time, was in these elevators found by test to be between 70 and 75%.

|

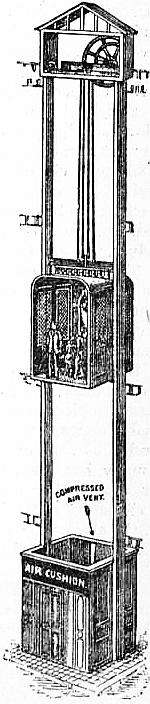

| Fig. 3. Safety Air-Cushion. |

Safety devices constitute perhaps the most important of the later improvements in elevator construction where passengers are carried. The simplest and, where practicable, most certain of them is the “air-cushion”, a chamber Safety devices. into which the cage drops if detached or from any cause allowed to fall too rapidly to the bottom, compression of the air bringing it to rest without shock (fig. 3). This chamber must be perfectly air-tight, except in so far as a purposely arranged clearance around the sides, diminishing downwards and in well-established proportion, is adjusted to permit a “dash-pot” action and to prevent rebound. The air-cushion should be about one-tenth the depth of the elevator shaft; in high buildings it may be a well 20 or 30 ft. deep. The Empire building, in New York, is twenty storeys in height, the total travel of the cage is 287 ft., and the air-cushion is 50 ft. deep, extending from the floor of the third storey to the bottom of the shaft. Sliding doors of great strength, and automatic in action, at the first and second floors, are the only openings. The shaft is tapered for some distance below the third floor, and then carried straight to the bottom. An inlet valve admits air freely as the cage rises, and an adjusted safety-valve provides against excess pressure. A “car,” falling freely from the twentieth storey, was checked by this arrangement without injury to a basket of eggs placed on its floor. Other safety devices consist of catches under the floor of the cage, so arranged that they are held out of engagement by the pull on the cables. But if the strain is suddenly relieved, as by breakage of a cable or accident to the engine or motor, they instantly fly into place and, engaging strong side-struts in the shaft, hold the car until it can be once more lifted by its cables. These operate well when the cables part at or near the car, but they are apt to fail if the break occurs on the opposite side of the carrying sheaves at the top of the shaft, since the friction and inertia of the mass of the cables may in that case be sufficient to hold the pawls out of gear either entirely or until the headway is so great as to cause the smashing of all resistances when they do engage.

Another principle employed in safety arrangements is the action of inertia of parts properly formed and attached. Any dangerous acceleration of the cage causes the inertia of these parts to produce a retardation relative to the car which throws into action a brake or a catch, and thus controls the motion within safe limits or breaks the fall. The hydraulic brake has been used in this apparatus, as have mechanical and pneumatic apparatus. This control of the speed of fall is most commonly secured by the employment of a centrifugal or other governor or regulator. The governor may be on the top of the cage and driven by a stationary rope fixed between the top and bottom of the shafts, or it may be placed at the top of the shaft and driven by a rope travelling with the car. Its action is usually to trip into service a set of spring grips or friction clutches, which, as a rule, grasp the guides of the cage and by their immense pressure and great resultant friction bring the cage to rest within a safe limit of speed, time and distance. A coefficient of friction of about 15% is assumed in their design, and this estimate is confirmed by their operation. Pressures of 10 tons or more are sometimes provided in these grips to ensure the friction required. There are many different forms of safety device of these various classes, each maker having his own. The importance of absolute safety against a fall is so great that the best builders are not satisfied with any one form or principle, but combine provisions against every known danger, and often duplicate such precautions against the most common accidents.

The “travelling staircase,” which may be classed among the passenger elevators, usually consists of a staircase so constructed that while the passenger is ascending it the whole structure is also ascending at a predetermined rate, so that the progress made is the sum of the two rates of motion. The system of “treads and risers” is carried on a long endless band of chain sustained by guides holding it in its desired line, and rendering at either end over cylinders or sprockets. The junctions between the stairway and the upper or lower floors are ingeniously arranged so as to avoid danger of injury to the passengers.

Freight elevators have the same general forms as the passenger elevators, but are often vastly larger and more powerful, and are not as a rule fitted up for such heights of lift, or constructed with such elaborate provision for safety or with any special finish. Elevators raising grain, coal, earth and similar materials, such as can be taken up by scooping into a bucket, or can be run into and out of the bucket by gravity, constitute a class by themselves, and are described in the article Conveyors.

The term “grain elevator” is often used to include buildings as well as machinery, and it is not unusual in Europe to hear a flour-mill, with its system of motor machinery, mills, elevator and storage departments, spoken of as an “American elevator” (see Granaries).