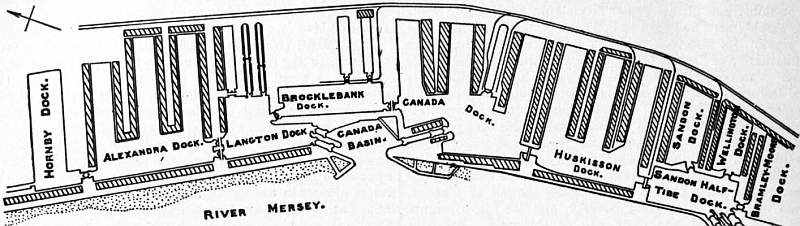

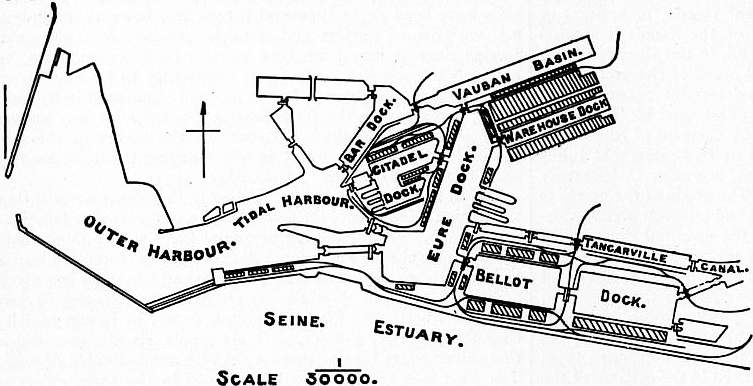

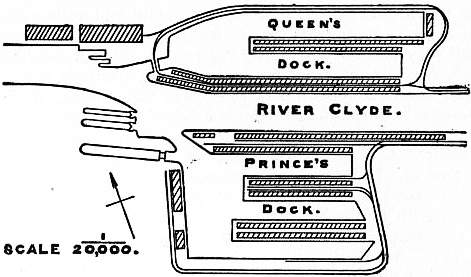

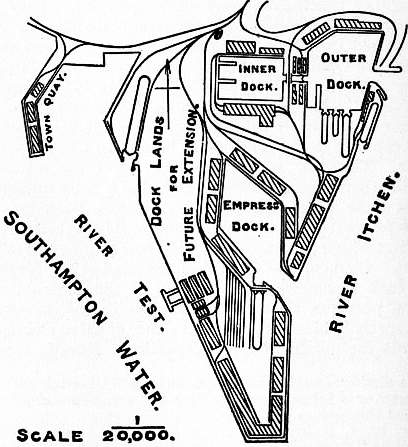

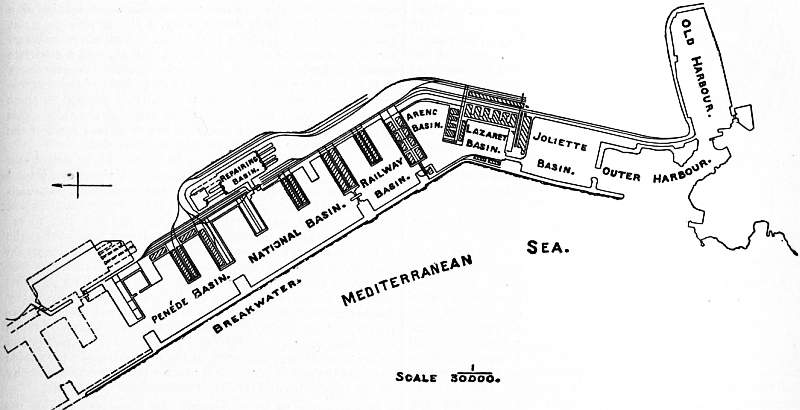

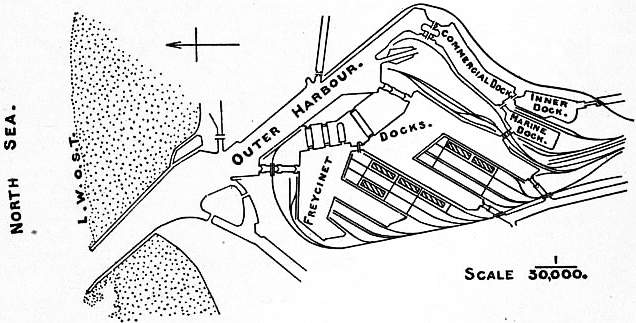

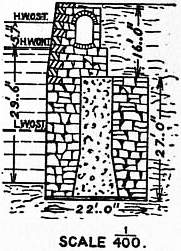

Dock, in marine and river engineering. Vessels require to lie afloat alongside quays provided with suitable appliances in sheltered sites in order to discharge and take in cargoes conveniently and expeditiously; and a basin constructed for this purpose, surrounded by quay walls, is known as a dock. The term is specially applied to basins adjoining tidal rivers, or close to the sea-coast, in which the water is maintained at a fairly uniform level by gates, which are closed when the tide begins to fall, as exemplified by the Liverpool and Havre docks (figs. 1 and 2). Sometimes, however, at ports situated on tidal rivers near their tidal limit, as at Glasgow (fig. 3), Hamburg and Rouen, and at some ports near the sea-coast, such as Southampton (fig. 4) and New York, the tidal range is sufficiently moderate for dock gates to be dispensed with, and for open basins and river quays to serve for the accommodation of vessels. For ports established on the sea-coast of tideless seas, such as the Mediterranean, on account of the rivers being barred by deltas at their outlets, like the Rhone and the Tiber, and thus rendered inaccessible, open basins, provided with quays and protected by breakwaters, furnish the necessary commercial requirements for sea-going vessels, as for example at Marseilles (fig. 5), Genoa, Naples and Trieste. These open basins, however, are precisely the same as closed docks, except for the absence of dock gates, and the accommodation for shipping at the quays round basins in river ports is so frequently supplemented by river quays, that closed docks, open basins and river quays are all naturally included in the general consideration of dock works.

|

| Fig. 1.—Liverpool Docks, North End. Scale 1⁄20,000. |

|

| Fig. 2.—Havre Docks and Outer Harbour. |

|

| Fig. 3.—Glasgow Docks. |

|

| Fig. 4.—Southampton Docks and River Quays. |

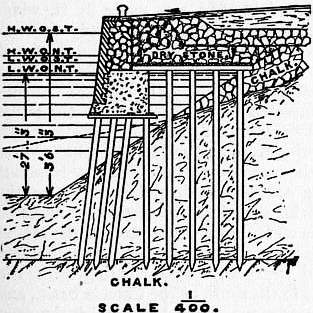

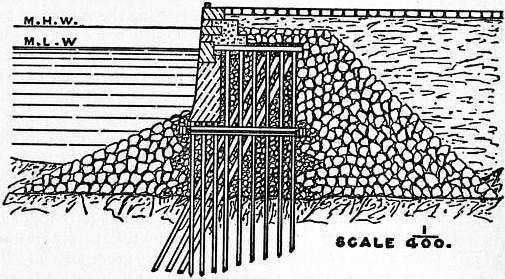

Low-lying land adjoining a tidal river or estuary frequently provides suitable sites for docks; for the position, being more or less inland, is sheltered; the low level reduces the excavation required for forming the docks, and enables the excavated Sites for Docks. materials to be utilized in raising the ground at the sides for quays, and the river furnishes a sheltered approach channel. Notable instances of these are the docks of the ports of London, Liverpool, South Wales, Southampton, Hull, Belfast, St Nazaire, Rotterdam, Antwerp and Hamburg. Sometimes docks are partially formed on foreshores reclaimed from estuaries, as at Hull, Grimsby, Cardiff, Liverpool, Leith and Havre; whilst at Bristol, a curved portion of the river Avon was appropriated for a dock, and a straight cut made for the river. By carrying docks across sharp bends of tidal rivers, upper and lower entrances can be provided, thereby conveniently separating the inland and sea-going traffic; and of this the London, Surrey Commercial, West India, and Victoria and Albert docks are examples on the Thames and Chatham dockyard on the Medway. Occasionally, when a small tidal river has a shallow entrance, or an estuary exhibits signs of silting up, docks alongside, formed on foreshores adjoining the sea-coast, are provided with a sheltered entrance direct from the sea, as exemplified by the Sunderland docks adjacent to the mouth of the river Wear, and the Havre docks at the outlet of the Seine estuary (fig. 2). Some old ports, originally established on sandy coasts where a creek, maintained by the influx and efflux of the tide from low-lying spaces near the shore, afforded some shelter and an outlet to the sea across the beach, have had their access improved by parallel jetties and dredging; and docks have been readily formed in the low-lying land only separated by sand dunes from the sea, as at Calais, Dunkirk (fig. 6) and Ostend (see Harbour). In sheltered places on the sea-coast, docks have sometimes been constructed on low-lying land bordering the shore, with direct access to the sea, as at Barrow and Hartlepool; whilst at Mediterranean ports open basins have been formed in the sea, by establishing quays along the foreshore, from which wide, solid jetties, lined with quay walls, are carried into the sea at intervals at right angles to the shore, being sheltered by an outlying breakwater parallel to the coast, and reached at each end through the openings left between the projecting jetties and the breakwater, as at Marseilles (fig. 5) and Trieste, and at the extensions at Genoa (see Harbour) and Naples. Where, however, the basins are formed within the partial protection of a bay, as in the old ports of Genoa and Naples, the requisite additional shelter has been provided by converging breakwaters across the opening of the bay; and an entrance to the port is left between the breakwaters. The two deep arms of the sea at New York, known as the Hudson and East rivers, are so protected by Staten Island and Long Island that it has been only necessary to form open basins by projecting wide jetties or quays into them from the west and east shores of Manhattan Island, and from the New Jersey and Brooklyn shores, at intervals, to provide adequate accommodation for Atlantic liners and the sea-going trade of New York.

|

| Fig. 5.—Port of Marseilles. Basins and Extensions. |

The accessibility of a port depends upon the depth of its approach channel, which also determines the depth of the docks or basins to which it leads; for it is useless to give a depth to a dock much in excess of the depth down to Approach channels. which there is a prospect of carrying the channel by which it is reached. The great augmentation, however, in the power and capacity for work of modern dredgers, and especially of suction dredgers in sand (see Dredge), together with the increasing draught of vessels, has resulted in a considerable increase being made in the available depth of rivers and channels leading to docks, and has necessitated the making of due allowance for the possibility of a reasonable improvement in determining the depth to be given to a new dock. On the other hand, there is a limit to the deepening of an approach channel, depending upon its length, the local conditions as regards silting, and the resources and prospects of trade of the port, for every addition to the depth generally involves a corresponding increase in the cost of maintenance.

|

| Fig. 6.—Dunkirk Docks and Jetty Channel. |

|

| Fig. 7.—Tilbury Docks. |

At tidal ports the available depth for vessels should be reckoned from high water of the lowest neap tides, as the standard which is certain to be reached at high tide; and the period during which docks can be entered at each tide depends upon the nature of the approach channel, the extent of the tidal range and the manner in which the entrance to the docks is effected. Thus where the tidal range is very large, as in the Severn estuary, the approach channels to some of the South Wales ports are nearly dry at low water of spring tides, and it would be impossible to make these ports accessible near low tide; whereas at high water, even of neap tides, vessels of large draught can enter their docks. At Liverpool, with a rise of 31 ft. at equinoctial spring tides, owing to the deep channel between Liverpool and Birkenhead and into the outer estuary of the Mersey in Liverpool Bay, maintained by the powerful tidal scour resulting from the filling and emptying of the large inner estuary, access to the river by the largest vessels has been rendered possible, at any state of the tide, by dredging a channel through the Mersey bar; but the docks cannot be entered till the water has risen above half-tide level, and the gates are closed directly after high water. A large floating landing-stage, however, about half a mile in length, in front of the centre of the docks, connected with the shore by several hinged bridges and rising and falling with the tide, enables Atlantic liners to come alongside and take on board or disembark their passengers at any time.

|

| Fig. 8.—Barry Docks. |

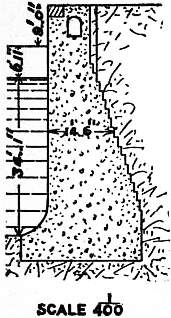

Comparatively small tidal rivers offer the best opportunity of a considerable improvement in the approach channel to a port; for they can be converted into artificially deep channels by dredging, and their necessary maintenance is somewhat aided by the increased influx and efflux of tidal water due to the lowering of the low-water line by the outflow of the ebb tide being facilitated by the deepening. Thus systematic, continuous dredging in the Tyne and the Clyde has raised the Tyne ports and Glasgow into first-class ports. In large tidal rivers and estuaries, docks should be placed alongside a concave bank which the deep navigable channel hugs, as effected at Hull and Antwerp, or close to a permanently deep channel in an estuary, such as chosen for Garston and the entrance to the Manchester ship canal at Eastham in the inner Mersey estuary, and for Grimsby and the authorized Illingham dock in the Humber estuary; for a channel carried across an estuary to deep water requires constant dredging to maintain its depth. Occasionally, extensive draining works and dredging have to be executed to form an adequately deep channel through a shifting estuary and shallow river to a port, as for instance on the Weser to Bremerhaven and Bremen, on the Seine to Honfleur and Rouen, on the Tees to Middlesborough and Stockton, on the Ribble to Preston, on the Maas to Rotterdam and on the Nervion to Bilbao (see River Engineering). Southampton possesses the very rare combination of advantages of a well-sheltered and fairly deep estuary, a rise of only 12 ft. at spring tides, and a position at the head of Southampton Water at the confluence of two rivers (fig. 4), so that, with a moderate amount of dredging and the construction of quays along the lower ends of the river with a depth of 35 ft. in front of them at low water, it is possible for vessels of the largest draught to come alongside or leave the quays at any state of the tide. This circumstance has enabled Southampton to attract some of the Atlantic steamers formerly running to Liverpool.

Ports on tideless seas have to be placed where deep water approaches the shore, and where there is an absence of littoral drift. The basins of such ports are always accessible for vessels of the draught they provide for; but they require most efficient protection, and, unlike tidal ports, they are not able on exceptional occasions to admit a vessel of larger draught than the basins have been formed to accommodate. Occasionally, an old port whose approach channel has become inadequate for modern vessels, or from which the sea has receded, has been provided with deep access from the sea by a ship canal, as exemplified by Amsterdam and Bruges; whilst Manchester has become a seaport by similar works (see Manchester Ship Canal). In such cases, however, perfectly sheltered open basins are formed inland at the head of the ship canal, in the most convenient available site; and the size of vessels that can use the port depends wholly on the dimensions and facility of access of the ship canal.

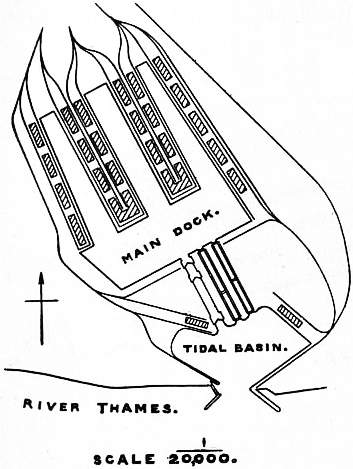

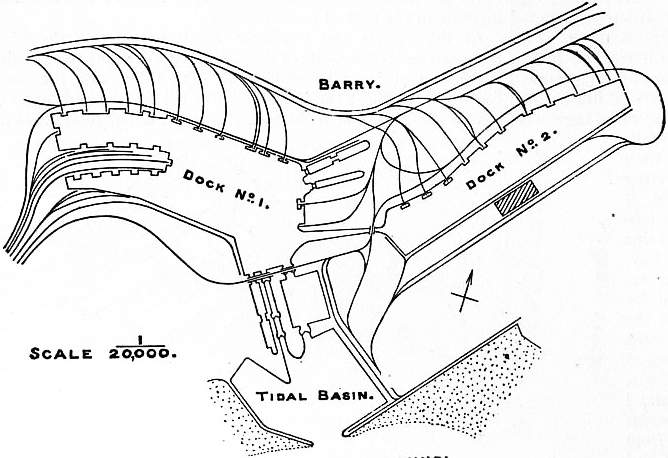

Docks require to be so designed that they may provide the maximum length of quays in proportion to the water area consistent with easy access for vessels to the quays; but often the space available does not admit of the adoption of Design of Docks. the best forms, and the design has to be made as suitable as practicable under the existing conditions. On this account, and owing to the small size of vessels in former times, the docks of old ports present a great variety in size and arrangement, being for the most part narrow and small, forming a sort of string of docks communicating with one another, and provided with locks or entrances at suitable points for their common use, as noticeable in the older London and Liverpool docks. Though narrow timber jetties were introduced in some of the wider London docks for increasing the length of quays by placing vessels alongside them, no definite arrangement of docks was adopted in carrying out the large Victoria and Albert docks between 1850 and 1880; whilst the Victoria dock was made wide with solid quays, provided with warehouses, projecting from the northern quay wall, thereby affording a large accommodation for vessels lying end on to the north quay, the Albert dock subsequently constructed was given about half the width of the earlier dock, but made much longer, so that vessels lie alongside the north and south quays in a long line. This change of form, however, was probably dictated by the advantage of stretching across the remainder of the wide bend, in order to obtain a second entrance in a lower reach of the river. The Tilbury docks, the latest and lowest docks on the Thames, were constructed on the most approved modern system, consisting of a series of branch docks separated by wide, well-equipped solid quays, and opening straight into a main dock or basin communicating with the entrance lock, in which vessels can turn on entering or leaving the docks (fig. 7). The most recently constructed Liverpool docks, also, at the northern end have been given this form; and the older docks adjoining them to the south have been transformed by reconstruction into a similar series of branch docks opening into a dock alongside the river wall, leading to a half-tide basin or river entrances (fig. 1). The Manchester and Salford docks were laid out on a precisely similar system, which was also adopted for the most recent docks at Dunkirk (fig. 6) and Prince’s dock at Glasgow (fig. 3), and at some of the principal Rhine ports; whilst the Alexandra dock at Hull resembles it in principle. The basins in tideless seas have naturally been long formed in accordance with this system (fig. 5). The Barry docks furnish an example of the special arrangements for a coal-shipping port, with numerous coal-tips served by sidings (fig. 8).

Tidal basins, as they are termed, are generally interposed in the docks of London between the entrance locks and the docks, with the object of facilitating the passage of vessels out of and into the docks before and after high water, by lowering the Tidal and half-tide basins. water in the basin as soon as the tide has risen sufficiently, and opening the lock gates directly a level has been formed with the tide in the river. Then the vessels which have collected in the basin, when level with the dock, are readily passed successively into the river. The incoming vessels are next brought into the basin, and the gates are closed; and the water in the basin having been raised to the level in the dock, the gates shutting off the basin from the dock when the water was lowered are opened, and the vessels are admitted to the dock. In this manner, by means of an inner pair of gates, the basin can be used as a large lock without unduly altering the water-level in the dock, and saves the delay of locking most of the vessels out and in, the lock being only used for the smaller vessels leaving early or coming in late on the tide. Similar tidal basins have also been provided at Cardiff, Penarth, Barry (fig. 8), Sunderland, Antwerp and other docks.

The large half-tide docks introduced at the most modern Liverpool docks (fig. 1) serve a similar purpose as tidal basins; but being much larger, and approached by entrances instead of locks, the exit and entrance of vessels are effected by lowering their water-level on a rising tide, and opening the gates, which are then closed at high water to prevent the lowering of the water-level in the dock, and to avoid closing the gates against a strong issuing current.

The tidal basins outside the locks at Tilbury and Barry are quite open to the tide, and have been carried down to 24 ft. and 16 ft. respectively below low water of spring tides, in order to afford vessels a deep sheltered approach to the lock in each case, available at or near low water (figs. 7 and 8). Such basins, however, open to a considerable tidal range where the water is densely charged with silt, are exposed to a large deposit in the fairly still water, and their depth has to be constantly maintained by sluicing or dredging.

Where the range of tide is moderate, or on large inland rivers, docks or basins are usefully supplemented by river quays, which though subject to changes in the water-level, and exposed to currents in the river, are very convenient for access, River quays. and are sometimes very advantageously employed in regulating a river and keeping up its banks when deepened by dredging. Generally 10 to 12 ft. is the limit of the tidal range convenient for the adoption of open basins and river quays; but the banks of the Tyne have been utilized for quays, jetties and coal-staiths, with a somewhat larger maximum tidal range; and a long line of quays stretching along the right bank of the Scheldt in front of Antwerp, constructed so as to regulate this reach of the river, accommodates a large sea-going traffic, with a rise at spring tides of 15 ft.

When a dock has to be formed on land, the excavation is effected by men with barrows and powerful steam navvies, loading into wagons drawn in trains by locomotives to the place of deposit, usually to raise the land at the sides for forming Excavations for docks. quays. Directly the underground water-level is reached, the water has to be removed from the excavations by pumps raising the inflowing water from sumps, lined with timber, sunk down below the lowest foundations at suitable positions, so that the lower portions of the dock walls and sills of the lock or entrance may be built out of water. A cofferdam has to be constructed extending out from the bank of the river or approach channel in front of the site of the proposed entrance or lock, so that the excavations for the entrance to the dock may be pushed forwards, and the lock or entrance built under its protection. Sometimes the lowest portion of the excavation for the dock can be accomplished economically by dredging, after the dock walls and lock have been completed and the water admitted.

Where a dock is partially or wholly constructed on reclaimed land, the reclamation bank for enclosing the site and excluding the tide has to be undertaken first by tipping an embankment from each end with wagons, protected and consolidated along its outer toe by rubble stone or chalk. When the ends of the embankments are approaching one another, it is essential to connect them by a long low bank of selected materials brought up gradually in successive layers, and retaining the water in the enclosure to the level of this bank, so that the influx and efflux of the tide, filling and emptying the reclaimed area, may take place over a long length, and in smaller volume as the low bank is raised. In this way a reduction is effected of the tidal current in and out, which in the case of a large enclosure and a considerable tidal range, would create such a scour in the narrowing gap between two high embankments as to wash away their ends and prevent the closing of the gap. Occasionally the final closure is effected by lowering timber panels in grooves between a series of piles driven down at intervals across the gap. On the closing of the reclamation bank the water is pumped out; and the excavation is carried on in the ordinary manner. It is very important that such an embankment should be carried well above the level of the highest tide which might be raised by a high wind; and in exposed sites, the outer slope of the bank should be protected by pitching from the action of waves, for any overtopping or erosion of the bank might result in a large breach through it, and the flooding of the works inside.

Docks are generally surrounded by walls retaining the quays, alongside which vessels lie for discharging and taking in cargoes. In order to ascertain the nature of the strata upon which these walls have to be founded, borings are taken at the Foundations for dock walls. outset to the requisite depth at intervals near the line of the walls, but inside the dock area if the piercing of quicksand is anticipated, as in excavating for the foundations, these holes might give rise to the outflow, under pressure, of underlying quicksand into the foundations. As docks are generally formed near rivers or estuaries, these strata are commonly alluvial; but being situated at some depth below the surface, they are usually fairly hard. When they consist of gravel, clay or firm sand, the walls can be founded on the natural bottom excavated a few feet below the bottom of the dock, their weight being somewhat distributed by making them rest on a broad bed of concrete filling up the excavation at the bottom. When, however, fine sand or silt charged with water, or quicksand is met with at the required depth, the necessary pumping and excavation for the foundations might occasion the influx of sand or silt with the water into the excavations, leading to settlement and slips; or the soft stratum might be too thick to remove. The wall may then be founded on bearing piles driven down to a solid stratum, and having their tops joined together by walings and planking, or by a layer of concrete, upon which the wall is built. Or the soft stratum can be enclosed with a double row of sheet piling along the front and back of the line of wall, by which it sometimes becomes sufficiently confined and consolidated to sustain the weight of the wall on a broad foundation of concrete; or it can be excavated without any danger of sand or silt running in from outside; whilst the sheet piling at the back relieves the wall to some extent from the pressure of the earth behind it, and in front retains the wall from sliding forwards. Firmer foundations have been obtained by sinking brick, concrete or masonry wells through soft ground to a solid stratum, upon which the dock wall is built. Clusters of small concrete cylinders, in sets of three in front, and a line of double cylinders at the back, were used for the foundations of the walls of Prince’s dock at Glasgow. Wells of rubble masonry were sunk in the silty foreshore of the Seine estuary for the walls of the Bellot docks at Havre; and they served as piers, connected by arches, for the foundations of a continuous dock wall above, being carried down to a considerable depth through alluvium at the St Nazaire, Bordeaux and Rochefort docks. These well foundations, derived from the old Indian system, are built up upon a curb, sometimes furnished with a cutting edge underneath, and gradually sunk by excavating inside; and eventually the central hollow is filled up solid with concrete or masonry.

|

| Fig. 9.—Havre Bellot Dock Wall. |

|

| Fig. 10.—Liverpool Dock Wall. |

|

| Fig. 11.—Tilbury Basin Wall. |

|

| Fig. 12.—Barry Dock Wall. |

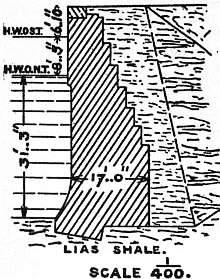

The walls round a dock serve as retaining walls to keep up the quays; and though they have the support of the water in front of them when the docks are in use, they have to sustain the full pressure of the filling at the back on the completion of the dock before the water is admitted. They have, accordingly, to be increased in Dock walls. thickness downwards to support the pressure increasing with the depth. This pressure, with perfectly dry material, would be represented by the weight of half the prism of filling between the natural slope of the material behind and the back of the wall; but the pressure is often increased by the accumulation of water at the back, which, with fine silty backing, is liable to exert a sort of fluid pressure against the wall proportionate to the density of the mixture of silt and water. The increase of thickness towards the base used formerly to be effected by a batter on the face, as well as by steps out at the back; but the vertical form now given to the sides of large vessels necessitates a corresponding fairly vertical face for the wall, to prevent the upper part of the vessel being kept unduly away from the quay. Examples of the most modern types of dock walls are given in figs. 9 to 12.

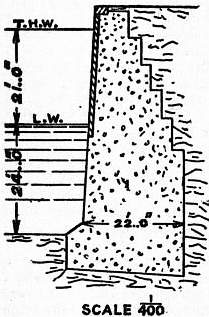

The height of a dock wall depends upon the depth of water always available for vessels, at tideless sea-ports and at ports removed from tidal influences, such as Manchester, Bruges and the ports on the Rhine; this depth should not be less than 28 to 30 ft. for large sea-going vessels, together with a margin of 5 to 8 ft. above the normal water-level for the quays, and the foundations below. At tidal ports, however, an addition has to be made equal to the difference in height between the high-water levels of spring and neap tides; so that at ports with a large tidal range, such as the South Wales ports on the Severn estuary and Liverpool, specially high dock walls are necessary. Under normal conditions, a dock wall should be given a width at a height half-way between dock-bottom and quay-level, equal to one-third of its height above dock-bottom, and a width of half this height at dock-bottom.

Dock walls are constructed of masonry, brickwork or concrete, or of concrete with a facing of masonry or brickwork. Masonry is adopted where large stone quarries are readily accessible, in the form of rubble masonry with dressed stone on the face, as for instance at the Hull and Barry docks, and forms a very durable wall; but strong overhead staging carrying powerful gantries is necessary for laying large blocks. Brickwork has been often used where bricks are the ordinary building material of the district or can be made on the works, and requires only ordinary scaffolding; and harder or pressed bricks are employed for the facework. Concrete is very commonly resorted to now where sand and stones are readily procured; and where clean, sharp sand and gravel are found in thick layers in the excavations for a dock, as in the alluvial strata bordering the Thames, dock walls can be constructed cheaply and economically with concrete deposited within timber framing, dispensing with regular scaffolding and skilled labour. Such walls require to be given a facing of stronger concrete, or of blue bricks, as at Tilbury, to guard against abrasion by vessels, chains and ropes; and dock walls are commonly provided at the top with granite or other hard stone coping where the wear is greatest. The foundations for dock walls are excavated in a trench below dock-bottom, only lined with timbering where the faces of the trench cannot stand for a short time without support, and with sheet piling through very unstable silt or sand; and the trench is conveniently filled up solid with concrete, carried out in short lengths in untrustworthy ground. To reduce the amount of filling behind the wall, the excavation at the back above dock-bottom, preparatory for the trench, is given as steep a slope as practicable, supported sometimes towards the base by timbering and struts; but occasionally the wall is built within a timbered trench carried down to the required depth, before the excavation for the dock in front of it has been executed, as effected at Tilbury. The filling at the back is thus reduced to a minimum, and the lower portion of the excavation can be accomplished by dredging, if expedient, after the admission of the water, the dock wall in this way being exposed to the least possible pressure behind.

The walls of open basins are often constructed out of water precisely like dock walls, as in the case of the basins forming the Manchester, Bruges and Glasgow docks; and basin walls open to the tide, as at Glasgow and in the tidal basin outside Tilbury docks (fig. 7), differ only from dock walls in being exposed to variations in the pressure at the back resulting from the lowering of the water-level in front, which is, indeed, shared to some extent by the walls round closed docks where the difference in the high-water levels of springs and neaps is considerable. The walls, however, round basins in tideless seas, such as Marseilles, occasionally those inside harbours, and especially quay walls along rivers and round open basins alongside rivers, have to be constructed under water.

|

| Fig. 13.—Marseilles Quay Wall. |

|

| Fig. 14.—Antwerp Quay Wall, founded by compressed air. |

|

| Fig. 15.—Caracciolo Jetty Quay Wall, Genoa. |

|

| Fig. 16.—Glasgow River Quay Wall. |

|

| Fig. 17.—Rouen Quay Wall. |

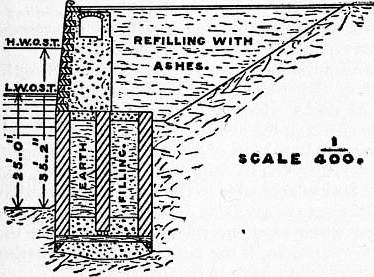

At Marseilles, the simple expedient was long ago adopted of constructing the quay walls lining the basins formed in the sea, by depositing tiers of large concrete blocks on a rubble foundation, one on top of the other, till they Open basin and river quay walls founded under water. reached sea-level, and then building a solid masonry quay wall out of water on the top up to quay-level, faced with ashlar (fig. 13), the wall being backed by rubble for some distance behind up to the water-level. The same system was employed for the quay walls at Trieste, and at Genoa and other Italian ports. A quay wall inside Marmagao harbour, on the west coast of India, was erected on a foundation layer of rubble by the sloping-block system, to provide against unequal settlement on the soft bottom (see Breakwater). The quay walls alongside the river Liffey, and round the adjacent basins below Dublin, were erected under water by building rubble-concrete blocks of 360 tons on staging carried out into the water, from which they were lifted one by one by a powerful floating derrick, which conveyed the block to the site, and deposited it on a levelled bottom at low tide in a depth of 28 ft., raising the wall a little above low water. After a row of these blocks had been laid, and connected together by filling the grooves formed at the sides and the interstices between the blocks with concrete, a continuous masonry wall faced with ashlar was built on the top out of water. A quay wall was built up to a little above low water on a similar principle at Cork, with three smaller blocks as a foundation, in lengths of 8 ft. Cylindrical well foundations have been extensively used for the foundations of the quay walls along the Clyde, formerly made of brick, but subsequently of concrete, sunk through a considerable variety of alluvial strata, but mostly sand and gravel fully charged with water. Compressed air in bottomless caissons has been increasingly employed in recent years for carrying down the subaqueous foundations of river quay walls, through alluvial deposits, to a solid stratum. About 1880, a long line of river quays was commenced in front of Antwerp, extending in the central portion a considerable distance out into the Scheldt, with the object of regulating the width of the river simultaneously with the provision of deep quays for sea-going vessels; and the quay wall was erected, out of water, on the flat tops of a series of wrought-iron caissons, 82 ft. long and 29½ ft. wide, constructed on shore, floated out one by one to their site in the river between two barges, and gradually lowered as the wall was built up inside a plate-iron enclosure round the roof of the caisson, which was eventually sunk by aid of compressed air through the bed of the river to a compact stratum (fig. 14). The weight of the wall counteracted the tendency of the caisson and the enclosure above it to float; and the caisson, furnished with seven circular wrought-iron shafts, provided with air-locks at the top for the admission of men and materials and for the removal of the excavations, was gradually carried down by excavating inside the working chamber at the bottom, 6¼ ft. high, till a good foundation was reached. The working chamber was then filled with concrete through some of the shafts, the plate-iron sides of the upper enclosure were removed to be used for another length of wall, the shafts were drawn out and the hollows left by them filled with concrete, the apertures between adjacent lengths were closed at each face with wooden panels and filled with concrete, and a continuous quay wall was completed above. The most recent quay walls constructed in the old harbour at Genoa were founded under water on a rubble mound in a similar manner by the aid of compressed air (fig. 15). Quay walls also on the Clyde have been founded on caissons, consisting of a bottomless steel structure, surmounted by a brick superstructure having hollows filled with concrete, in lengths of 80 ft. and 27 ft., and widths of 18 ft. and 21 ft. respectively, carried down by means of compressed air from 54 to 70 ft. below quay-level, on the top of which a continuous wall of concrete, faced with brickwork, and having a granite coping, was built up from near low-water level (fig. 16). In many cases where soft strata extend to considerable depths, river quays and basin walls have been constructed by building a light quay wall upon a series of bearing and raking piles driven into, and if possible through, the soft alluvium. Thus the walls along the Seine, and round the basins at Rouen, were built upon bearing piles carried down through the alluvial bed of the river to the chalk. The lower portion of the quay wall was constructed of concrete faced with brickwork within water-tight timber caissons, resting upon the piles at a depth of 9¾ ft. below low water; and upon this a rubble wall faced with bricks was erected from low water to quay-level, backed by rubble stone laid on a timber flooring supported by piles, together with chalk, to form a quay right back to the top of the slope of the bank of the deepened river (fig. 17). The quay walls of the open basins bordering the Hudson river at New York have had, in certain parts, to be founded on bearing piles combined with raking piles, driven into a thick bed of soft silt where no firm stratum could be reached, and where, therefore, the weight could only be borne by the adherence of the long piles in the silt. Before driving the piles, however, the silt round the upper part of the piles and under the quay wall was consolidated by depositing small stones in a trench dredged to a depth of 30 ft. below low water; the piles were driven through these stones, and were further kept in place by a long toe of rubble stone in front and a backing of rubble stone behind carried nearly up to quay-level, behind which a light filling of ashes and earth was raised to quay-level. The slight quay wall resting upon the front rows of bearing piles was carried up under water by 70-ton concrete blocks deposited by means of a floating derrick; and the upper part of the wall was built of concrete faced with ashlar masonry (fig. 18). The basin and quay walls at Bremen, Bremerhaven and Hamburg were built on a series of bearing and raking piles driven down to a firm stratum, the wall being begun a few feet below low water. At Southampton, ferro-concrete piles were employed in constructing the deep quays; and a wharfing of timber pilework has been frequently used for river quays.

Where the increase of trade is moderate and the conditions of the traffic permit, and also at coal-shipping ports, economy in construction is obtained by giving sloping sides to a portion of a dock in place of dock walls, the slope being pitched where necessary with stone; and the length of the slope projecting into a dock is sometimes reduced by substituting sheet piling for the slope at the toe up to a certain height. By this arrangement jetties can be carried out across the slope as required, enabling vessels to lie against their ends; and coal-tips are very conveniently extended out across the slope at suitable intervals (fig. 8).

As dock walls, especially before the admission of water into the dock, constitute high retaining walls, not infrequently founded upon soft or slippery strata, and backed up with the excavated materials from alluvial beds, into which water is liable to percolate, Failures of dock walls. they are naturally exposed under unfavourable conditions to the danger of failure. A dock wall erected on unsatisfactory foundations is liable, where the bottom is soft, to settle down at its toe, owing to the pressure at the back, and to fall forwards into the dock, as occurred at Belfast; or where the silty bottom slips forward under the weight of the backing, the wall may follow the slip at the bottom and settle down at the back, falling to some extent backwards, as exemplified by the failure of the Empress basin wall at Southampton. The most common form, however, of failure is the sliding forwards of a dock wall, with little or no subsidence, on a silty or slippery stratum under the pressure imposed by the backing. Thus the Kidderpur dock walls furnish an instance of sliding forwards on muddy silt, and part of the South West India dock walls on two underlying, detached, slippery seams of London clay.

To avoid these failures with untrustworthy foundations, great care has to be exercised in selecting the best hard material available, unaffected by water, for the backing, which should be brought up in thin, horizontal layers carefully consolidated; and where there is a possibility of water accumulating at the back, pipes should be introduced at intervals near the bottom right through the wall in building it, and rubble stone deposited close to the back of the wall, so as to carry off any water from behind, these pipes being stopped up just before the water is let into the dock. These precautions, moreover, are assisted by reducing the amount of backing to a minimum in the construction of the wall, best effected by building the wall inside a timbered trench. The liability to slide forwards can be obviated by carrying down the foundations of the wall sufficiently below dock-bottom to provide an efficient buttress of earth in front of the wall, and also by making the base of the wall slope down towards the back, thereby forcing the wall in sliding forwards to mount the slope, or to push forward a larger mass of earth; whilst a row of sheet piling in front of the foundations offers a very effectual impediment to a forward movement, and, in combination with bearing piles, prevents settlement at the toe in soft ground. In very treacherous foundations it may be advisable to defer the completion of the backing till after the admission of the water; but the additional stability given to a retaining wall or reservoir dam by an ample batter in front, is precluded in dock walls by the modern requirements of vessels.

|

| Fig. 18.—New York Quay Wall, Hudson river. |

Silt accumulates in docks where the lowering of the water-level by locking, the drawing down of half-tide basins, and the raising of the water at spring tides, involve the admission of considerable volumes of tidal water heavily charged with silt, which is deposited in still water and has to be periodically Maintenance of depth. removed by dredging. To avoid this, the water is sometimes replenished from some clear inland source, an arrangement adopted at some of the South Wales ports opening into the muddy Severn estuary, and at the Alexandra dock, Hull, to exclude the silty waters of the Humber. At the Kidderpur docks on the Húgli, the water from the river for replenishing the docks is conducted by a circuitous canal, in which it deposits its burden of silt before it is pumped into the docks.

In order to deal expeditiously with the cargoes and goods brought into and despatched from docks, numerous sidings communicating with the railways of the district are arranged along the quays, which are also provided Equipment on quays. with steam, hydraulic or electric travelling cranes at intervals alongside the docks, basins or river, for discharging or loading vessels, and with sheds and warehouses for the storage of merchandise, &c., the arrangements depending largely upon the special trade of the port. Though different sources of power are sometimes made use of at different parts of the same port, as for example at Hamburg, where the numerous cranes are worked by steam, hydraulic power or most recently by electricity, and a few by gas engines, it is generally most convenient to work the various installations by one form of power from a central station. Water-pressure has been very commonly used as the motive power at docks, being generated by a steam-engine and stored up by one or more accumulators, from which the water is transmitted under pressure through strong cast-iron pipes to the hydraulic engines which actuate the cranes, lifts, coal-tips, capstans, swing-bridges and gate machinery throughout the docks (see Power Transmission: Hydraulic). The intermittent working of the machinery in docks results in a considerable variation in the power needed at different times; but economical working is secured by arranging that when the accumulators are full, steam is automatically shut off from the pumping engines, but is supplied again as soon as water is drawn off. Electricity affords another means for the economical transmission of power to a distance suited for intermittent working; as far back as 1902 it was being adopted at Hamburg as the source of power for the machinery of the extensive additional basins then recently opened for traffic.

At ports where the principal trade is the export of coal from neighbouring collieries, special provision has to be made for its rapid shipment. Coal-tips, accordingly, are erected at the sides of the dock in these ports, with sidings on Coal-tips. the quays at the back for receiving the trains of coal trucks, from which two lines of way diverge to each coal-tip, one serving for the conveyance of the full wagons one by one to the tip, after passing over a weigh-bridge, and the other for the return of the empty wagons to the siding where the empty train is made up for returning to the colliery (fig. 8). Each full wagon is either run at a low level upon a cradle at the tip, then raised on the cradle within a wrought-iron lattice tower to a suitable height, and lastly, tipped up at the back for discharging the coal; or it is brought along a high-level road on to a cradle raised to this level on the tower, and tipped up at this or some slightly modified level. The coal is discharged down an adjustable iron shoot, gradually narrowed so as to check the fall; and on first discharging into the hold of a vessel, an anti-breakage box is suspended below the mouth of the shoot. When full, this is lowered to the bottom of the hold and emptied, thereby gradually forming a cone of coal upon which the coal can be discharged directly from the shoot without danger of breakage. Other contrivances are also adopted with the same object.

In designing dock works, it is expedient to make provision, as far as possible, for future extensions as the trade of the port increases. Generally this can be effected alongside tidal rivers and estuaries by utilizing sites lower down the river, as carried out on Dock extensions. the Thames for the port of London, or reclaiming unoccupied foreshores of an estuary, as adopted for extensions of the ports of Liverpool, Hull and Havre. At ports on the sea-coast of tideless seas, it is only necessary to extend the outlying breakwater parallel to the shore line, and form additional basins under its shelter, as at Marseilles (fig. 5) and Genoa (see Harbour). Quays also along rivers furnish very valuable opportunities of readily extending the accommodation of ports. Ports, however, established inland like Manchester, though extremely serviceable in converting an inland city into a seaport, are at the disadvantage of having to acquire very valuable land for any extensions that may be required; but, nevertheless, some compensation is afforded by the complete shelter in which the extensions can be carried out, when compared with Liverpool, where the additions to the docks can only be effected by troublesome reclamation works along the foreshore to the north, in increasingly exposed situations.

Dock Entrances and Locks.—The size of vessels which a port can admit depends upon the depth and width of the entrance to the docks; for, though the access of vessels is also governed by the depth of the approach channel, this channel is often capable of being further deepened to some extent by dredging; whereas the entrance, formed of solid masonry or concrete, cannot be adapted, except by troublesome and costly works sometimes amounting to reconstruction, to the increasing dimensions of vessels. Accordingly, in designing new dock works with entrances and locks, it is essential to look forward to the possible future requirements of vessels. The necessity for such forethought is illustrated by the rapid increase which has taken place in the size of the largest ocean liners. Thus the “City of Rome,” launched in 1881, is 560 ft. long, and 52¼ ft. beam, and has a maximum recorded draught of 27½ ft.; the “Campania” and “Lucania,” in 1893, measure 600 ft. by 65 ft.; the “Oceanic,” in 1899, 685½ ft. by 68¼ ft., with a maximum draught of 311⁄3 ft.; the “Baltic,” in 1903, 709 ft. by 75 ft., with a maximum draught of 31¾ ft.; and the “Lusitania” and “Mauretania,” launched in 1906, 787½ ft. by 88 ft.

The width and depth of access to docks are of more importance than the length of locks; for docks which are reached through entrances with a single pair of gates have to admit vessels towards high water when the water-level in the Dimensions of entrances and locks. dock is the same as in the approach channel, or through a half-tide basin drawn down to the level of the water outside, and are therefore accessible to vessels of any length, provided the width of the entrance and depth over the sill are adequate; whilst at docks which are entered through locks, vessels which are longer than the available length of the lock can get in at high water when both pairs of gates of the lock are open. Open basins are generally given an ample width of entrance, and river quays also are always accessible to the longest and broadest vessels; but in a tidal river the available depth has to be reckoned from the lowest low water of spring tides, instead of from the lowest high water of neap tides, if the vessels in the open basins and alongside the river quays have to be always afloat.

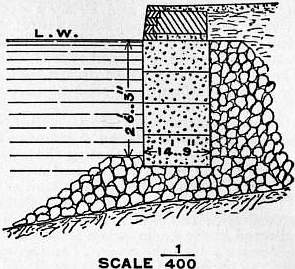

Many years ago the Canada lock at Liverpool, the outer North lock at Birkenhead, the Ramsden lock and entrance at Barrow-in-Furness, and the Eure entrance at Havre, were given a width of 100 ft. Probably this was done with the view of admitting paddle steamers, since subsequent entrances at Liverpool were given widths of 80 and 65 ft.; whereas none of the locks in the port of London has been made wider than 80 ft., which has been the standard maximum width since the completion of the Victoria dock in 1866. The widest locks at Cardiff are 80 ft., and the entrance to the Barry docks is the same; but the lock of the Alexandra dock, Hull, opened in 1885, was made 85 ft. wide. At Liverpool, where the access to the docks is mainly through entrances, on account of the small width between the river and the high ground rising at the back, and where ample provision has to be made for the largest Atlantic liners, though the entrances to the Langton dock, completed in 1881, leading to the latest docks at the northern end were made 65 ft. wide, with their sills 3 ft. below low water of spring tides and 20½ ft. below high water of the lowest neap tides, the two new entrances to the deepened Brunswick dock near the southern end, giving access to the adjacent reconstructed docks, completed in 1906, were made 80 and 100 ft. wide, with sills 28 ft. below high water of the lowest neap tides. Moreover, the three new entrances to the new Sandon half-tide dock, completed in 1906, communicating with the reconstructed line of docks to the south of the Canada basin, and with the latest northern extensions of the Liverpool docks, were made 40 ft. wide with a depth over the sill of 24½ ft., and 80 and 100 ft. wide on each end of the central entrance, with sills 29 ft. below high water of the lowest neap tides, each entrance being provided with two pairs of gates, in case of any accident occurring to one pair, according to the regular custom at Liverpool. Powers were also obtained in 1906 for the construction of a half-tide dock and two branch docks to the north of the Hornby dock, which are to be reached from the river by two entrances designed to be 130 ft. wide, with sills 38½ ft. below high water of the lowest neap tides, so as to meet fully the assumed future increase in the beam and draught of the largest vessels; whilst the authorized extension of the river wall northwards will enable additional docks to be constructed in communication with these entrances when required.

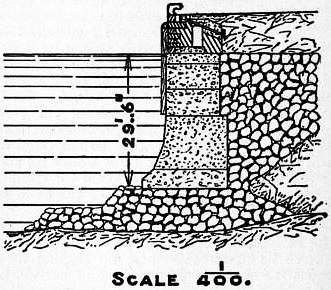

Though, with the exception of Southampton and Dover, other British ports do not aim, like Liverpool, at accommodating the largest Atlantic liners at all times, the depths of the sills at the principal ports have been increased in the most recent extensions. Thus at the port of London the sills of the first lock of the Albert dock were 26½ ft. below high water of neap tides, and of the second lock adjoining, 32½ ft. deep; whilst the sills of the lock of the Tilbury docks are 40½ ft. below high water of neap tides. Moreover, in spite of the great range of tide at the South Wales ports on the Severn estuary, the available depth at high water of neap tides of 25 ft. at the Roath lock, Cardiff, was increased in the lock of the new dock to 31½ ft.; the depth at the entrance to the Barry docks, opened in 1889, was 29½ ft., but at the lock opened in 1896 was made 411⁄3 ft.; whilst a depth of 34 ft. has been proposed for the new lock of the Alexandra dock extension at Newport, nearly 10 ft. deeper than the existing lock sills there. Similar improvements in depth have also been made or designed at other ports to provide for the increasing draught of vessels.

The length of locks has also been increased, from 550 ft. at the Albert dock, to 700 ft. at Tilbury in the port of London, from 300 ft. to 550 ft. at Hull, and from 350 ft. to 660 ft. at Cardiff. The lock at the Barry docks is 647 ft. long, though only 65 ft. wide. A lock constructed in connexion with the improvement works at Havre, carried out in 1896-1907, was given an available length of 805 ft. and a width of 98½ ft., with a depth over the sills of 34¾ ft. at high water of neap tides.

|

| Fig. 19.—Barry Docks, Entrance. |

Entrances with a single pair of gates, closing against a raised sill at the bottom and meeting in the centre, have to be made long enough to provide a recess in each side wall at the back to receive the gates when they are opened, and to form a buttress in front on Entrances to docks. each side to bear the thrust of the gates when closed against a head of water inside. A masonry floor is laid on the bottom in continuation of the sill, serving as an apron against erosion by water leaking between or under the gates, and by the current through the sluiceways in the gates, when opened for scouring the entrance channel or to assist in lowering the water in a half-tide dock for opening the gates (fig. 19). A sluiceway in each side wall, closed by a vertical sluice-gate, generally provided in duplicate in case of accidents and worked by a machine actuated by hydraulic pressure, enables the half-tide basin to be brought down to the level of the approach channel outside with a rising tide, so that vessels may be brought into or passed out of the basin towards high water. The advantages of these entrances are, that they occupy comparatively little room where the space is limited, and are much less costly than locks; whilst in conjunction with a half-tide basin they serve the same purpose as a lock with a rising tide. Vessels also pass more readily through the short entrances than through locks; and as entrances are only used towards high water, their sills need not be placed so low as the outer sills of locks to accommodate vessels of large draught. On the other hand, they are accessible for a more limited period at each tide than locks; and they do not allow of the exclusion of silt-bearing tidal water, and therefore necessitate a greater amount of dredging in the docks, and especially in half-tide basins, for maintenance. Entrances, however, at large ports are frequently supplemented by the addition of a lock at some convenient site, rendering the ports accessible for the smaller class of vessels for some time before and after high water, as for instance at Liverpool, Barry, Havre and St Nazaire. A small basin with an entrance at each end—an arrangement often adopted—is in reality, for all practical purposes, a lock with a very large lock-chamber. An entrance or passage with gates has also to be provided at the inner end of a large half-tide basin like the basins adopted at Liverpool, to shut off the half-tide basin from the docks to which it gives access, and maintain their water-level when the water is drawn down in the basin to admit vessels before high tide.

Reverse gates pointing outwards are sometimes added in passages to docks and at entrances, to render the water-level in one set of docks independent of adjacent docks, to exclude silty tidal water and very high tides, and also to protect the gates of outer entrances in exposed situations from swell, which might force them open slightly and lead to a damaging shock on their closing again.

Locks differ from entrances in having a pair of gates with arrangements similar to an entrance at each end, separated from one another by a lock-chamber, which should be large enough to receive the longest and broadest vessel coming regularly Locks at docks. to the port. These dock locks are similar in principle to locks on canals and canalized rivers, but are on a much larger scale. The lock-chamber has its water raised or lowered in proportion to the difference in level between the water-level in the dock and the water in the entrance channel, by passing water, when the gates are closed at both ends, from the dock into the lock-chamber or from the lock-chamber into the entrance channel, through large sluiceways in the side walls, controlled, as at entrances, by vertical sluice-gates. In this way the vessel is raised or lowered in the chamber, till, when a level has been reached, the intervening pair of gates is opened and the vessel is passed into the dock or out to the channel. Generally the upper and lower sills of a lock are at the same level, a foot or two higher than dock-bottom; and the depth at which they are laid is governed by the same considerations as the sill of an entrance. Vessels longer than the available length between the two pairs of gates can be admitted close to high water, when the water in the dock and outside is at the same level, and both pairs of gates can be opened. When the range of tide at a port is large, and the depth in the approach channel is sufficient to allow vessels to come up or go out some time before and after high water, and also where the water in the dock is kept up to a high level from an inland source to exclude very silty tidal water, it is expedient to reduce the cost of construction by limiting the depth of the excavations for the dock, and consequently also the height of the dock walls, to what is necessary to provide a sufficient depth of water below high water of the lowest neap tides, or below the water-level to which the water in the dock is always maintained, for the vessels of largest draught frequenting the port, or those which may be reasonably expected in the near future. The upper sill of the lock is then determined by the level of dock-bottom; but the lower sill is taken down approximately to the depth of the bottom of the approach channel, or to the depth to which it can be carried by dredging, so as to enable the lock to admit or let out at any time all vessels which can navigate the approach channel. Thus, for instance, the outer and intermediate sills of the lock at the Barry docks are 9 ft. lower then the upper sill.

The foundations for the sill and side walls at each end of a lock, and also for the side walls and invert commonly enclosing the lock-chamber at the sides and bottom, are generally constructed simultaneously with the dock works, under shelter of a cofferdam across the entrance channel, and in the excavations kept dry by means of pumps. The foundations under the sills and adjacent side walls are carried down to a lower level than the rest, and if possible to a water-tight stratum, to prevent infiltration of water under them owing to the water-pressure on the upper side of the gates; or sometimes one or two rows of sheet piling have been driven across the lock under the sills to an impermeable stratum, to stop any flow. The foundations for the sills consist usually of concrete deposited in a trench extended out under the adjoining side walls. The sill, projecting generally about 2 ft. above the adjacent gate floor over which the gates turn, is built of granite; and the same material is also used for the hollow quoins in which the heelpost, or pivot, of the dock gates turns, and which, together with the sills, are exposed to considerable wear. The side walls of the lock-chamber are very similar in construction to the dock walls; but they are strengthened against the loss of water-pressure in front of them when the water is lowered in the chamber by an inverted arch of masonry, brickwork or concrete, termed an “invert,” laid across the bottom of the chamber along its whole length, against which the toe of each side wall abuts and effectually prevents any forward movement. The side walls also, alongside the gates at each end, abut against a thick level gate floor and apron, and, moreover, are considerably widened to provide space for the sluiceways and gate machinery.

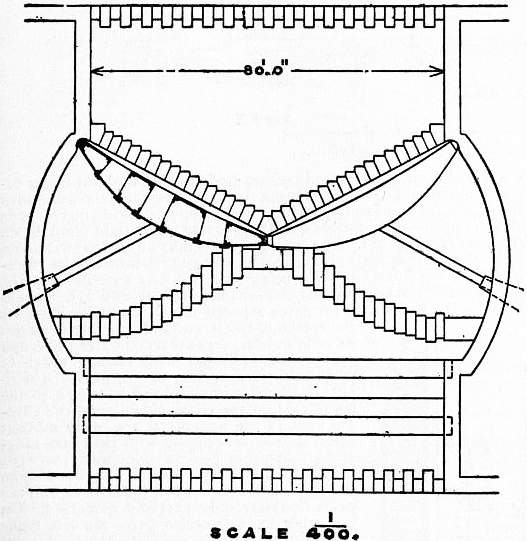

The new Florida lock (fig. 20), forming the main entrance through the new approach harbour and tidal harbour to the Eure dock and other docks of the port of Havre, is the largest lock hitherto constructed. It has an available length of chamber between the gates of 805 ft., a width of 98½ ft., and depths over the sills of 15¾ ft. at the lowest low water of spring tides, 23½ ft. at low water of neap tides, 35 ft. at high water of neap tides, and 40½ ft. at high water of spring tides. Owing to the alluvial stratum at the site of the lock close to the Seine estuary, of which it doubtless at one time formed part, the foundations for the sill and side walls or heads at each end of the lock were executed by aid of compressed air. The foundations for these heads were carried down to an impermeable stratum by means of two bottomless caissons, filled eventually with concrete, 213½ ft. long across the lock and 105 ft. wide in the line of the lock at the upper end, and 206¾ ft. long and 116½ ft. wide at the lower end, to a depth of 18 ft. below the sill at the upper end, and 41 ft. at the lower end, owing to the dip down seawards and southward of the water-tight stratum. These caissons were provided for their sinkage with temporary dams of masonry closing the opening of the lock at the extremities of each caisson, enabling the gates to be subsequently erected under their shelter. The junctions between the foundations of the heads and the adjacent foundations were effected by small movable caissons carried down in recesses provided in the buried caissons. The connexions with the adjacent quay walls were accomplished by two supplementary side caissons at the end of each head; and the north side wall of the lock was founded by means of seven bottomless caissons sunk by aid of compressed air, on account of the proximity of the tidal harbour on that side. The south side wall was founded for a length of about 200 ft. at its western end in an excavated trench kept dry by pumping; but the greater portion was founded in a dredged trench in which bearing piles were driven under water, on which the masonry was built in successive layers, about 3¼ ft. thick, in a movable caisson 93½ ft. long and 37¾ ft. wide; whilst a bottomless caisson, left in the work, was employed for founding about 100 ft. of wall at the eastern end. The bed of concrete also, 10 ft. thick, forming the floor of the chamber, was carried out for 82 ft. at the western end in the open air, and the remainder in the same movable caisson as used for the south wall. Two sluiceways on each side running the whole length of the lock, differing 6½ ft. in level, communicate with the lock-chamber through openings in the side walls, 67¼ ft. apart, and provide for the filling and emptying of the chamber.

|

| Fig. 20.—Florida Lock, Havre Docks, Sections and Plan. |

The gates closing the entrances and locks at docks are made of wood or of iron. In iron gates, the heelpost, or a vertical closing strip attached to the outer side of the gate close to the heelpost, the meeting-post at the end of each gate closing against Dock gates. each other when the gates are shut, and the sill piece fitting against the sill are generally made of wood. Wooden gates consist of a series of horizontal framed beams, made thicker and put closer together towards the bottom to resist the water-pressure increasing with the depth, fastened to the heelpost and meeting-post at the two ends and to intermediate uprights, and supporting water-tight planking on the inner face (fig. 21). Iron gates have generally an outer as well as an inner skin of iron plates braced vertically and horizontally by plate-iron ribs, the horizontal ribs being placed nearer together and the plates made thicker towards the bottom (figs. 22 and 23). Greenheart is the wood used for gates exposed to salt water, as it resists the attack of the teredo in temperate climates. As cellular iron gates are made water-tight, and have to be ballasted with enough water to prevent their flotation, or are provided with air chambers below and are left open to the rising tide on the outer side above, the gates are light in the water and are easily moved; whereas greenheart gates with their fastenings are considerably heavier than water, so that a considerable weight has to be moved when the water is somewhat low in the dock and the gates therefore only partially immersed. On the other hand, wooden gates are less liable than iron gates to be seriously damaged if run into by a vessel.

|

||

| Fig. 21.—Wooden Dock Gate. | Fig. 22.—Iron Segmental Dock Gate. | Fig. 23.—Straight Iron Dock Gate. |

Dock gates are sometimes made straight, closing against a straight sill (figs. 20 and 23); and occasionally they are made segmental with the inner faces forming a continuous circular arc and closing against a sill corresponding to the outer curves of the gates (fig. 22), or by means of a projecting sill piece against a straight sill (fig. 21). More frequently the gates, curved on both faces, meet at an angle forming a Gothic arch in plan, and close by aid of a projecting piece against a straight sill, which in the Barry entrance gates is modified by making the outer faces nearly straight (fig. 19), giving an unusual width to the centre of the gates. The pressures produced by a head of water against these gates when closed depends not only on the form of the gates, but also upon the projection given to the angle of the sill in proportion to the width of the lock, which is known as the rise, and is generally placed at a distance along the centre line of the lock, from a line joining the centres of the heel-posts, of about one-fourth the width. With straight gates, the stresses consist, first of a transverse stress due to the water-pressure against the gate, which increases with the head of water and length of the gate; and secondly, of a compressive stress along the gate, resulting from the pressure of the other gate against its meeting-post, which is equal to half the water-pressure on the gate multiplied by the tangent of half the angle between the closed gates, varying inversely with the rise. Though an increase in the rise reduces this stress, it increases the length of the gate and the transverse stress, and also the length of the lock. By curving the gates suitably, the transverse stress is reduced and the longitudinal compressive stress is augmented, till at last, when the gates form a horizontal segmental arch, the stresses become wholly compressive and uniform in each horizontal section, increasing with the depth; and the total stress is equal to the pressure on a unit of surface multiplied by the radius of curvature. Though the water-pressure is most uniformly and economically borne by cylindrical gates, they are longer, and encroach more upon the lines of quay with their curved recesses than straighter gates; and, consequently, Gothic-arched gates are often preferred. Straight gates afford the greatest simplicity in construction.

|

|

| Fig. 24.—Sliding Caisson. | Fig. 25.—Ship Caisson. |

Gates in wide entrances or locks are generally supported towards their outer end by a roller running along a castiron roller-path on the gate floor (figs. 19, 21 and 22), as well as by the heelpost, fitted over a steel pivot at the bottom, and tied back against the hollow quoins at the top by anchor straps and bolts, on which the gate turns. In some cases, by placing the water ballast in iron gates close to the heelpost, a roller has been dispensed with, even, for instance, at the wide entrance at Havre (fig. 23). The gates are opened and closed, either by an opening and a closing chain for each gate, fastened on either side and worked from opposite side walls by hydraulic power, or by a single hydraulic piston or bar hinged to the inner side of each gate (figs. 19 and 20). The latter system has the advantages of being simpler and occupying less space in the side walls, of avoiding the slight loss of available depth over the sill due to the two closing chains crossing on the sill when the gates are open, and especially of keeping the gates closed against a swell in exposed sites.

A sliding or rolling caisson is occasionally placed across each end of a lock in place of a pair of dock gates, being Caissons drawn back into a recess at the side for opening docks. the lock. As a caisson chamber has to be covered for over to provide a continuous quay or roadway on the Caissons for docks. top, a lowering platform is supplied to enable the caisson to pass under the small girders spanning the top of the chamber, or the caisson is sunk down sufficiently (fig. 24). The caisson is furnished with an air chamber to give it flotation, which is adjusted by ballast according to the depth of water. The advantages of a caisson, as compared with a pair of gates, are that the gate recesses, gate floor, hollow quoins and arrangements for working in the side walls are dispensed with, so that the lock can be made shorter, and the work at each head is rendered less complicated. The caisson itself also serves as a very strong movable bridge, and therefore is often preferred at dockyards to dock gates. By improvements in the hauling machinery, a caisson can open or close a lock as quickly as dock gates; the caissons at Zeebrugge lock, at the entrance to the Bruges ship canal, are drawn across the lock or into their chamber by electricity in two minutes. A caisson is specially useful in cases where there may be a head of water on either side, as then it takes the place of two pairs of gates pointing in opposite directions, or for closing an entrance against a current. A caisson, however, requires a much larger amount of material than a pair of dock gates, and a considerable width on one side for its chamber, so that under ordinary conditions gates are generally used at docks.

A ship caisson, so called from its presenting some resemblance in section to the hull of a vessel, occupies too much time in being towed, floated into position, and sunk into grooves at the bottom and sides of an entrance for closing it, and then refloated and towed away for opening the entrance again, to be used at entrances and locks to docks (fig. 25). Being, however, simple in construction, taking up little space, and requiring no chamber or machinery for moving it, this form of caisson is generally used for closing the entrance to a graving dock, where it remains for several days in place during the execution of repairs to a vessel in the dock. A ship caisson only requires the admission of sufficient water to sink it when in position across the entrance to a graving dock; and this water has to be pumped out before it can be floated, and removed to some vacant position in the neighbouring dock till it is again required. Like a sliding or rolling caisson, it provides a bridge for crossing over the entrance of the graving dock when in position.

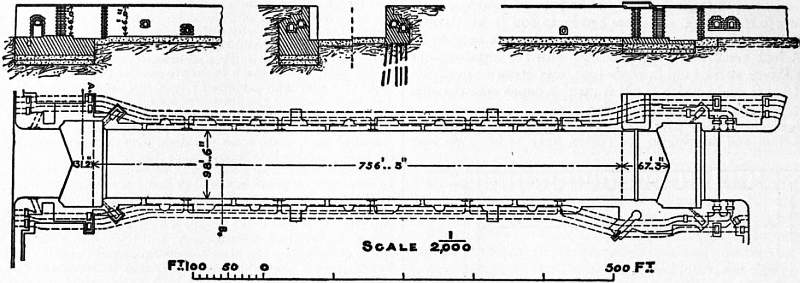

Graving Docks. - Provision has to be made at ports for the repairs of vessels frequenting them. The simplest arrangement is a timber gridiron, on which a vessel settles with a falling tide, and can then be inspected and slightly cleaned and repaired till the tide floats it again. Inclined slipways are sometimes provided, up which a vessel resting in a cradle on wheels can be drawn out of the water; and they are also used for shipbuilding, the vessel when ready for launching being allowed to slide down them into the water. Graving or dry docks, however, opening out of a dock, are the usual means provided for enabling the cleaning and repairs of vessels to be carried out.

|

| Fig. 26.—Plan of Southampton Graving Dock. |

|

| Fig. 27.—Cross Section of Southampton Graving Dock. |

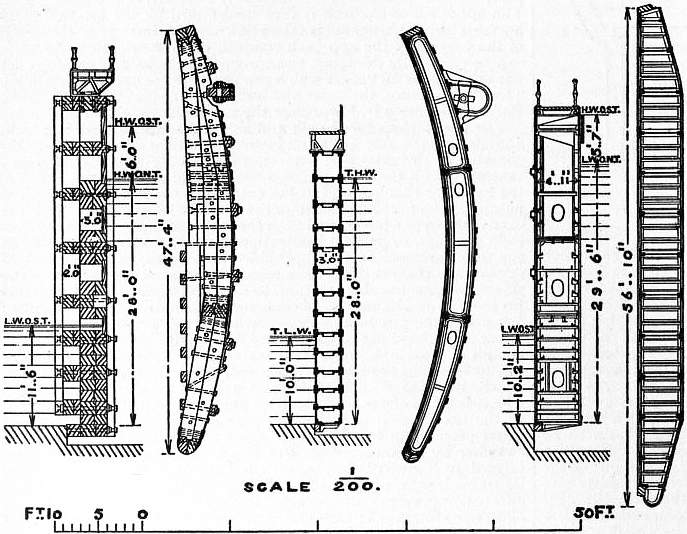

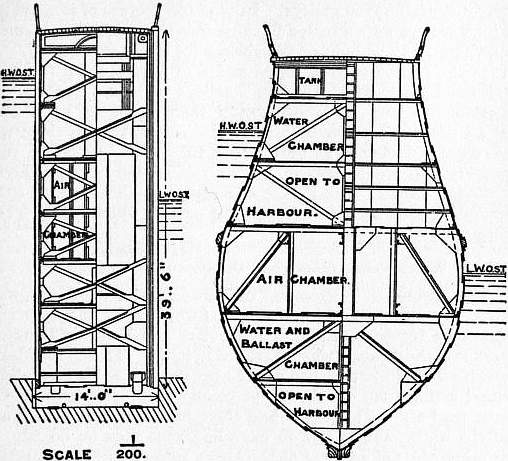

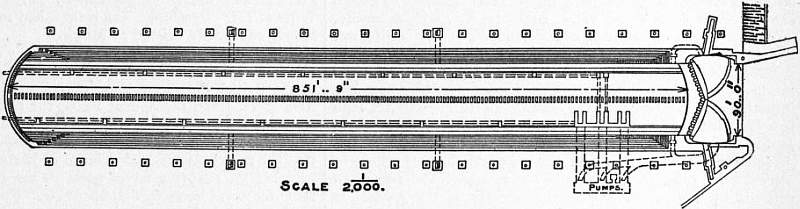

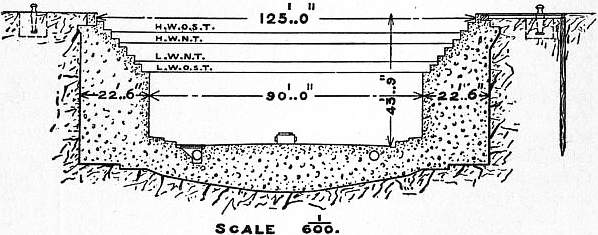

A graving dock consists of an enclosure, surrounded by side walls stepped on the face, and paved at the bottom with a thick floor sloping slightly down from the centre to drains along the sides, long enough to receive the longest vessel likely to come to the port. Its entrance, at the end adjoining the dock, is just wide enough to admit the vessel of greatest beam, and deep enough over the sill to receive the vessel of greatest draught, when light, at the lowest water-level of the dock (figs. 26 and 27). Graving docks are constructed of masonry, brickwork or concrete, or formerly in America of timber; they should be founded on a solid impervious stratum, or, where that is impracticable, they should be built upon bearing piles and enclosed within sheet piling, to prevent settlement and the infiltration of water under pressure below the dock. Keel blocks are laid along the centre line of the dock, for the keel of the vessel to rest on when the water is pumped out; and the vessel is further supported on each side by timber shores supported on the steps or “altars” of the side walls, which are lined with granite or other hard stone, or blue bricks, or, when constructed of concrete, with a facing of stronger concrete, to enable these altars to withstand the wear and shocks to which they are subjected. Steps and slides are provided at convenient places at the sides to give access for men and materials to the bottom of the dock; and culverts and drains lead the water to pumps for removing the water from the dock when the entrance has been closed, and to keep it dry whilst a vessel is under repair. Culverts in the side walls of the entrance enable water to be admitted for filling the dock to let the vessel out. Graving docks are generally closed by ship caissons; but where they open direct on to a tidal river, and there is some exposure, gates are adopted, or sometimes sliding caissons.

The dimensions of graving docks vary considerably with the nature of the trade and the date of construction; and sometimes an intermediate entrance is provided to accommodate two smaller vessels. The sizes of some of the largest graving docks are as follows: Liverpool, Canada dock, 925½ ft. long, 94 ft. width of entrance, and 29 ft. depth at the ordinary water-level in the dock; Southampton, 851¾ ft. by 90 ft., and 29½ ft. depth at high-water neaps (figs. 26 and 27); Tilbury, 875 ft. by 70 ft. by 31½ ft.; and Glasgow, 880 ft. by 80 ft. by 26½ ft.

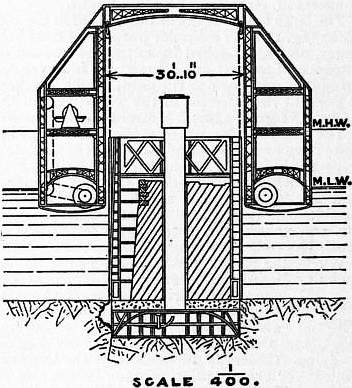

Floating Dry Docks.—Where there is no site available for a graving dock, or the ground is very treacherous, floating dry docks, built originally of wood, but more recently of iron or steel, have occasionally been resorted to. The first Bermuda dock towed across the Atlantic in 1869, and the new dock launched in 1902, 545 ft. by 100 ft., are notable examples. Water is admitted into the pontoon at the bottom to sink the dock sufficiently to admit a vessel at its open end; and then the water is pumped out of compartments in the pontoon till the vessel is raised out of water. It is only necessary to find a sheltered site, with a sufficient depth of water, for conducting the operations.