Coke (a northern English word, possibly connected with “colk,” core), the product obtained by strongly heating coal out of contact with the air until the volatile constituents are driven off; it consists essentially of carbon, the so-called “fixed carbon,” together with the incombustible matters or ash contained in the coal from which it is derived. In addition to these it almost invariably contains small quantities of hydrogen, oxygen and nitrogen, the whole, however, not exceeding 2 or 3%. It also contains water, the amount of which may vary considerably according to the method of manufacture. When produced rapidly and at a low heat, as in gas-making, it is of a dull black colour, and a loose spongy or pumice-like texture, and ignites with comparative ease, though less readily than bituminous coal, so that it may be burnt in open fire-places; but when a long-continued heat is used, as in the preparation of coke for iron and steel melting, the product is hard and dense, is often prismatic in structure, has a brilliant semi-metallic lustre and silvery-grey colour, is a conductor of heat and electricity, and can only be burnt in furnaces provided with a strong chimney draught or an artificial blast. The strength and cohesive properties are also intimately related to the nature and composition of the coals employed, which are said to be caking or non-caking according to the compact or fragmentary character of the coke produced.

Formerly coke was made from large coal piled in heaps with central chimneys like those of the charcoal burner, or in open rectangular clamps or kilns with air flues in the enclosing walls; but these methods are now practically obsolete, closed chambers or ovens being generally used. These vary considerably in construction, but may be classified into three principal types:—(1) direct heated ovens, (2) flue-heated ovens, (3) condensing ovens. In the first class the heating is done by direct contact or by burning the gases given off in coking within the oven, while in the other two the heating is indirect, the gas being burned in cellular passages or flues provided in the walls dividing the coking chambers, and the heat transmitted through the sides of the latter which are comparatively thin. The arrangement is somewhat similar to that of a gas-works retort, whence the name of “retort ovens” is sometimes applied to them. The difference between the second and third classes is founded on the treatment of the gases. In the former the gas is fired in the side flues immediately upon issuing from the oven, while in the latter the gases are first subjected to a systematic treatment in condensers, similar to those used in gas-works, to remove tar, ammonia and condensable hydrocarbons, the incondensable gases being returned to the oven and burned in the heating flues. These are generally known as “by-product ovens.”

The simplest form of coke oven, and probably that still most largely used, is the so-called “beehive oven.” This is circular in plan, from 7 to 12 ft. in diameter, with a cylindrical wall about 2½ ft. high and a nearly hemispherical roof with a Beehive oven. circular hole at the top. The floor, made of refractory bricks or slabs, is laid with a slight slope towards an arched opening in the ring wall, which is stopped with brickwork during the coking but opened for drawing the finished charge. The ovens are usually arranged in rows or banks of 20 to 30 or more, with their doors outwards, two rows being often placed with a longitudinal flue between them connected by uptakes with the individual ovens on either side. A railway along the top of the bank brings the coal from the screens or washery. The largest ovens take a charge of about 5 tons, which is introduced through the hole in the roof, the brickwork of the empty oven being still red hot from the preceding charge, and when levelled fills the cylindrical part nearly to the springing of the roof. The gas fires as it is given off and fills the dome with flame, and the burning is regulated by air admitted through holes in the upper part of the door stopping. The temperature being very high, a proportion of the volatile hydrocarbons is decomposed, and a film of graphitic carbon is deposited on the coke, giving it a semi-metallic lustre and silvery grey colour. When the gas is burned off, the upper part of the door is opened and the glowing charge cooled by jets of water thrown directly upon it from a hose, and it is subsequently drawn out through the open door. The charge breaks up into prisms or columns whose length corresponds to the depth of the charge, and as a rule is uniform in character and free from dull black patches or “black ends.” The time of burning is either 48 or 72 hours, the turns being so arranged as to avoid the necessity of drawing the ovens on Sunday. The longer the heat is continued the denser the product becomes, but the yield also diminishes, as a portion of the finished coke necessarily burns to waste when the gas is exhausted. For this reason the yield on the coal charged is usually less than that obtained in retort ovens, although the quality may be better. Coals containing at most about 35% of volatile matter are best suited for the beehive oven. With less than 25% the gas is not sufficient to effect the coking completely, and when there is a higher percentage the coke is brittle and spongy and unsuited for blast furnace or foundry use. The spent flame from the ovens passes to a range of steam boilers before escaping by the chimney.

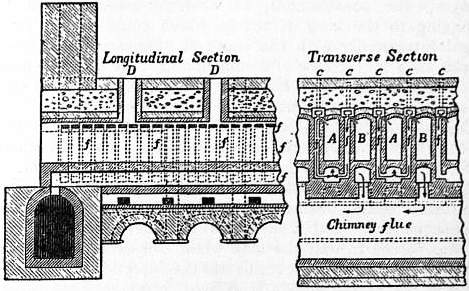

The retort oven, which is now generally displacing the beehive form in new installations, is made in a great variety of forms, the differences being mainly in the arrangement of the heating flues, but all have the central feature, the coking Retort oven. chamber, in common. This is a tubular chamber with vertical sides and cylindrical roof, about 30 ft. long, from 17 to 20 in. wide, and 6 or 7 ft. high, and closed at both ends by sliding doors which are raised by crab winches when the charge is to be drawn. The general arrangements of such an oven are shown in fig. 1, which represents one of the earliest and most popular forms, that of Evence Coppée of Brussels. The coking chambers A B connect by rectangular posts at the springing of the roof, where the gas given off from the top of the charge is fired by air introduced through c c. The flames pass downwards through the parallel flues f f along the bottom flue of one oven, and return in the opposite direction under the next to the chimney flue, a further part of the heat being intercepted by placing a range of steam boilers between the ovens and the chimney stack. The charging of the oven is done through the passages D D in the roof from small wagons on transverse lines of rails, the surface being raked level before the doors are closed and luted up. The time of coking is much less than in the beehive ovens and may be from 24 to 36 hours, according to the proportion of volatile matter present. When the gas is completely given off the doors are lifted and the charge is pushed out by the ram—a cast-iron plate of the shape of the cross section of the oven, at the end of a long horizontal bar, which is driven by a rack and pinion movement and pushes the block of coke out of the oven on to the wharf or bank in front where it falls to pieces and is immediately quenched by jets of water from a hose pipe. When sufficiently cooled it is loaded into railway wagons or other conveyances for removal. The ram, together with its motor, and boiler when steam is used, is mounted upon a carriage running upon a line of rails of about 2 ft. gauge along the back of the range of ovens, so that it can be brought up to any one of them in succession.

|

| Fig. 1.—Coppée’s Coke Oven. |

In some cases, instead of the small coal being charged through the roof of the oven and levelled by hand, it is formed into blocks by being stamped in a slightly moistened condition in a mould consisting of a bottom plate or peel on a racked rod like that of the ram, with movable sides and ends. This, when the ends are removed, is pushed forward into the oven, and the bottom plate is withdrawn by reversing the rack motion. The moulding box is mounted on a carriage like that of the ram, the two being sometimes carried on the same framing. The moulding is done at a fixed station in the centre of the range of ovens by a series of cast-iron stampers driven by an electric motor. This system is useful for coals low in volatile matter, which do not give a coherent coke under ordinary conditions.

In the distilling or by-product ovens the gases, instead of being burned at the point of origin, pass by an uptake pipe in the roof about the centre of the oven into a water-sealed collecting trough or hydraulic main, whence they are drawn by Condensing ovens. exhausters through a series of air and water cooled condensers and scrubbers. In the first or atmospheric condensers the tar is removed, and in the second ammoniacal water, which is further enriched by a graduated system of scrubbing with weak ammoniacal liquor until it is sufficiently concentrated to be sent to the ammonia stills. The first treatment by scrubbing with creosote or heavy tar oil removes benzene, after which the permanent gaseous residue consisting chiefly of hydrogen and marsh gas is returned to the ovens as fuel.

In the Otto-Hoffmann oven, one of the most generally used forms, vertical side flues like those of Coppée are adopted. The returned gas enters by a horizontal flue along the bottom of the coking chamber, divided into two parts by a mid-feather wall, and is fired by heated air from a Siemens regenerator on the substructure at one end, and the flame rising through one half of the side flues to a parallel collector at the top returns downwards through the flues of the other half and passes out to the chimney through a similar regenerator at the other end. The course of the gases is reversed at intervals of about an hour, as in the ordinary Siemens furnace, each end of the oven having its own gas supply. In the later modification known as the Otto-Hilgenstock, the regenerators are abandoned, but provision is made for more perfect distribution of the heat by a line of sixteen Bunsen burners in each wall; each of these serves two flues, the course of the flame being continuously upwards without reversal. In the newest Otto ovens the same system of burners is combined with regenerators. In the Bauer system, another vertical flue oven, each flue has its own burner, which is of a simplified construction.

In the Carvés oven, the earliest of the by-product ovens, the heating flues are arranged horizontally in parallel series along the entire length of the side walls, the gas being introduced from both ends but at different levels. This system was further developed by H. Simon of Manchester, who added a continuous air “recuperator” heated by the spent flame; this Simon-Carvés system has been extensively adopted in Great Britain. Another horizontal flue oven, the Semet-Solvay, is distinguished by the structure of the flues, which are independent of the dividing walls of the ovens, so that the latter can be made with thinner sides than those of the earlier systems, and are more readily repaired. In the horizontal ovens it is sometimes difficult to maintain the heat when the flues are continuous along the whole length of the wall, especially when the heating value of the gas is reduced by the removal of the heavy hydrocarbons. This difficulty is met by dividing the flues in the middle so as to shorten the length of travel of the flame, and working each end independently. The Hüssener and Koppers systems are two of the best-known examples of this modification.

Coke from retort ovens is not so dense or brilliant as that made in beehive ovens, but the waste being less there is a decided saving, apart from the value of the condensed products. In one instance the coke was found to be about 5% less efficient in the blast furnace, while the yield on the coal charged was increased 10%. In the further treatment of the condensed products by distillation the tar gives burning oil and pitch, the benzene is separated from the creosote oil by steam-heated stills, and the ammoniacal liquor, after some lime has been added to decompose fixed ammonium compounds, is heated to vaporize the ammonia, which is condensed in lead or copper-lined tanks containing strong sulphuric acid to produce a crystalline powder of ammonium sulphate, which accumulates in the receiver and is fished out from time to time. The yield of by-products averages about 1% of ammonium sulphate, about 3½% of tar, and 0.6 to 0.9% of benzene, of the weight of the coal carbonized. After the ovens have been heated and steam supplied for the machinery of the condensing plant and the coke ovens, there is usually a surplus of gas, which may be used for lighting or driving gas-engines. For the latter purpose, however, it is necessary to remove the last traces of tar, which acts very prejudicially in fouling the valves when the gas is not completely purified. The gas given off during the earlier part of the coking process is richer in heavy hydrocarbons and of a higher illuminating value than that of the later period when the temperature is higher. This property is utilized in several large coking plants in America, where the gas from the first ten hours’ working is drawn off by a second hydraulic main and sent directly to town gas-works, where it passes through the ordinary purifying treatment, the gas from the second period being alone used for heating the ovens.

Coke is essentially a partially graphitized carbon, its density being about midway between that of coal and graphite, and it should therefore occupy less space than the original coal; but owing to the softening of the charge a spongy structure is set up by the escaping gases, which acts in the other direction, so that for equal bulk coke is somewhat lighter than coal. It is this combination of properties that gives it its chief value in iron smelting, the substance being sufficiently dense to resist oxidation by carbon dioxide in the higher regions of the furnace, while the vesicular structure gives an extended surface for the action of heated air and facilitates rapid consumption at the tuyeres. Compact coke, such as that formed on the inner sides of gas retorts (retort carbon), can only be burned with great difficulty in small furnaces of special construction, but it gives out a great amount of heat.

The most deleterious constituents of coke are ash, sulphur and volatile constituents including water. As the coke yield is only from two-thirds to three-quarters of that of the coal, the original proportion of ash is augmented by one-third or one-half in the product. For this reason it is now customary to crush and wash the coal carefully to remove intermingled patches of shale and dirt before coking, so that the ash may not if possible exceed 10% in the coke. About one-half of the sulphur in the coal is eliminated in coking, so that the percentage in the coke is about the same. It should not be much above 1%. According to the researches of F. Wuest (Journ. Iron and Steel Inst., 1906) the sulphur is retained in a complex carbon compound which is not destroyed until the coke is actually consumed.

The older methods of coking and the earlier forms of retort ovens are described in J. Percy, Metallurgy, Jordan, Album du cours de metallurgie; Phillips and Bauerman, Handbook of Metallurgy, and other text-books. A systematic series of articles on the newer forms will be found in The Engineer, vol. 82, pp. 205-303 and vol. 83, pp. 207-231; see also Dürre, Die neuern Koksöfen (Leipzig, 1892); D. A. Louis, “Von Bauer and Brünck Ovens,” Journ. Iron and Steel Inst., 1904, ii. p. 293; C. L. Bell, “Hüssener Oven,” id., 1904, i. p. 188; Hurez, “A Comparison of Different Systems of Vertical and Horizontal Flue Ovens,” Bull. soc. industrie minérale, 1903, p. 777. A well-illustrated description of the Otto system in its American modification was issued by the United Gas & Coke Company of New York, in 1906.