Cellulose, the name given to both an individual—cellulose proper, in the restricted sense of a chemical individual—and to a group of substances, the celluloses or cellulose group, which constitute in infinitely varied forms the containing envelope of the plant cell. They are complex carbohydrates, or “saccharo-colloids” (Tollens), and are resolved by ultimate hydrolysis into monoses. The typical cellulose is represented by the empirical formula C6H10O5, identical with that of starch, with which it has many chemical analogies as well as physiological correlations. The representative “cellulose” is the main constituent of the cotton fibre substance, and is obtainable by treating the raw fibre with boiling dilute alkalis, followed by chlorine gas or bromine water, or simply by alkaline oxidants. The cellulose thus purified is further treated with dilute acids, and then exhaustively with alcohol and ether. Chemical filter-paper (Swedish) is practically pure cellulose, the final purification consisting in exhaustive treatment with hydrofluoric acid to remove silicious inorganic residues. The “cellulose” group, however, comprises a series of substances which, while presenting the characters generally similar to those of cotton cellulose, also exhibit marked divergences. The resemblances are maintained in their synthetical reactions; but reactions involving the decomposition of the complex show many variations. For example, cotton cellulose is difficultly hydrolysed; other celluloses are more or less readily split up by dilute acids, the extreme members readily yielding sugars: the hexoses—dextrose, mannose and galactose; and the pentoses—xylose and arabinose; these less resistant cell-wall constituents are termed hemi-celluloses.

The celluloses proper are essentially non-nitrogenous, though originating in the cell protoplasm. The cell-walls of the lower cryptogams, similarly purified, retain a notable proportion—2.0-4.0%—of constitutional nitrogen. When hydrolysed these fungoid celluloses yield, in addition to monoses, glucosamine and acetic acid. The celluloses of the phanerogams are generally associated, in a degree ranging from physical mixture to chemical union, with other complicated substances, constituting the “compound celluloses.” The nature of the associated groups affords a convenient classification into pecto-celluloses, ligno-celluloses and cuto-celluloses. Pecto-celluloses are so named because the associated substances—carbohydrates, together with their oxidation products, i.e. containing either two carbonyls (CO) in the unit group or carboxyl (CO·OH) groups in a complex—are readily hydrolysed by weak acids to the gelatinous “pectic acids” or their salts. Ligno-celluloses are the substances of lignified tissue, the non-cellulose constituents of which are characterized by the presence of benzenoid and furfuroid groups; and although essentially complex, they may be regarded as homogeneous, and are conveniently grouped under the name lignone. The lignone complex reacts, by its unsaturated groups, with the halogens. It is a complex containing but little hydroxyl; and is of relatively high carbon percentage (55.0-57.0%). Cuto-celluloses predominate in the protective coatings of plant organs, and are characterized by constituent groups, the decomposition products of which are compounds of the fatty series, and also wax alcohols, acids, cholesterols, &c.

The typical pecto-cellulose is the flax fibre, i.e. the bast fibre of the flax plant (Linum usitatissimum), as it occurs in the plant, or as the commercial textile fibre in its raw state. Rhea, or ramie, is another leading textile fibre in which the cellulose occurs associated with alkali-soluble colloidal carbohydrates. Pecto-celluloses are found in the stems of the Gramineae (cereal straws, esparto), and in the fibro-vascular bundles of monocotyledons used as textile and rope-making fibres. They are the chief constituents of the fleshy parenchyma of fruits, tubers, rhizomes. Ligno-celluloses find their chemical representative in the jute fibre. They constitute the woods, and are therefore of the widest distribution and the highest industrial utility. It is important to note that a complex having all the chemical characteristics of a ligno-cellulose occurs in a soluble colloidal form in the juice of the white currant. The formation of ligno-cellulose is the chemical equivalent of the morphological change of the plant cell known as “lignification.” The topical cuto-celluloses are the epidermal tissues of all growing plants or organs, which are easily detached from the underlying tissues which it is their function to protect. To subserve this function, they are extremely resistant to the attack of reagents. The associated groups are mostly of the normal saturated series, and of very high molecular weight.

Cellulose and Botanical Science.—The elaboration of cellulose, i.e. of the cell walls, and its morphological and physiological aspects are discussed in the articles Plants: Physiology, Anatomy: and Cytology; while in the article Coal the part played by cellulose in the formation of these deposits receives treatment: here we may deal with its general relation to agriculture. In the analysis of fodder plants and other vegetable produce, the residue obtained after successive acid and alkaline hydrolysis is the “crude fibre” of the agricultural chemist, and is generally taken as a measure of the actual cellulose contents of the raw material. We give in tabular form the average percentage of crude fibre in typical food-stuffs and agricultural produce:—

Seeds

| Seeds of Cereals. | Per cent of Fibre. |

Leguminous and Oil Seeds. |

Per cent of Fibre. |

| Wheat | 2.8 | Rape | 6.4 |

| Barley | 6.3 | Cotton | 7.5 |

| Oats | 9.0 | Beans | 10.0 |

| Maize | 5.2 | Peas | 10.0 |

| Rye | 8.0 | Lentils | 10.0 |

| Rice | 2.5 | Vetches | 7.2 |

Fodder Crops

| Stems and Foliage of Root Crops. |

Per cent of Fibre. |

Fodder Crops. | Per cent of Fibre.* |

Cereal Straws. | Per cent of Fibre. |

| White Turnip | 3.9 | Grasses | 32.0 | Oats | 60.68 |

| Swedish Turnip | 4.2 | Meadow Hay | 25.8 | Wheat | 75.77 |

| Carrot | 3.1 | Clover & Trefoil | 23.5 | Barley | 71.74 |

| Mangel | 2.6 | Vetches | 25.9 | ||

| Parsnip | 2.6 | Lucerne | 26.7 | ||

| Sainfoin | 28.7 | ||||

| * This percentage is calculated on airdry-produce containing 15% of water. | |||||

| Leguminous. | Oil Seeds. | Stems and Foliage of Root Crops. |

Fodder Crops. |

Cereal Straws. |

|

| Average % of water | 14 | 7 | 87 | 70-80 | 15 |

The above figures have a purely empirical value, since they represent a complicated mixture of various residues derived from the celluloses and compound celluloses. This mixture may be further resolved, and by special quantitative methods the proportions of actual cellulose, ligno-cellulose and cuto-celluloses estimated (J. König, Ber., 1906, 39, p. 3564). The figures are taken as an inverse measure of digestibility; at the same time it has been established that this group of relatively indigestible food constituents are more or less digestible and assimilable as flesh and fat producers. The percentage or coefficient of digestibility of the celluloses of the more important food-stuffs—green fodder, hay, straw and grains—varies from 20 to 75%. It has also been established that their physiological efficiency is, under certain conditions, quite equal to that of starch.

It must also be borne in mind that the indigestible food residues, as finally voided by the animal, have played an important mechanical part as an aid to digestion of those constituents more readily attacked in the digestive tract of animals. They are further an important factor of the agricultural cycle. Returned to the soil as “farm-yard manure,” mixed with other cellulosic matter which has served as litter, they add “fibre” to the soil and, as a mechanical diluent of the mineral soil components, maintain this in a more open condition, penetrable by the atmospheric gases, and promoting distribution of moisture. Further by breaking down, with production of “humus,” a complex of colloidal “unsaturated” bodies of acid function, they fulfil important chemical functions by interaction with the mineral soil constituents.

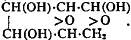

Chemistry of Cellulose.—Purified cotton cellulose, which is the definitive prototype of the cellulose group or series, is a complex of monoses or their “residues.” It is resolved by solution in sulphuric acid and subsequent hydrolysis of the esters thus produced into dextrose. This fundamental fact with its elementary composition, most simply expressed by the formula C6H10O5, has caused it to be regarded as a polyanhydride of dextrose. Forming, as it does, simple esters in the ratio of the reacting hydroxyls 3OH: C6H10O5, and taking into account its direct converson into ω-brom-methyl furfural (Fenton) a constitutional formula has been proposed by A.G. Green (Zeit. Farb. Textil Chem. 3, pp. 97 and 309 (1904)), which is a useful generalization of its reactions, and its ultimate relations to the simpler carbohydrates, viz.,  Green considers, moreover, that a group thus formulated may consistently represent the actual dimensions of the reacting unit, but that unit of larger dimensions, if postulated, is easily derived from the above by oxygen linkings.

Green considers, moreover, that a group thus formulated may consistently represent the actual dimensions of the reacting unit, but that unit of larger dimensions, if postulated, is easily derived from the above by oxygen linkings.

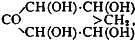

From another point of view the unit group has been formulated as  the main linking of such units in the complex taking place as between their respective CO and CH2 groups in the alternative enolic form CH—C(OH). This view gives expression to the genetic relations of the celluloses to the ligno-celluloses, to the tendency to carbon condensation as in the formation of coals, and pseudo-carbons, to the relative resistance of cellulose to hydrolysis, and its other points of differentiation from starch, and more particularly to the ketonic character of its carbonyl (CO) groups, which is also more in harmony with the experimental facts established by Fenton as to the production of methyl furfural.

the main linking of such units in the complex taking place as between their respective CO and CH2 groups in the alternative enolic form CH—C(OH). This view gives expression to the genetic relations of the celluloses to the ligno-celluloses, to the tendency to carbon condensation as in the formation of coals, and pseudo-carbons, to the relative resistance of cellulose to hydrolysis, and its other points of differentiation from starch, and more particularly to the ketonic character of its carbonyl (CO) groups, which is also more in harmony with the experimental facts established by Fenton as to the production of methyl furfural.

The probability, however, is that no simple molecular formula adequately represents the constitution of cellulose as it actually exists or indeed reacts. On the other hand, it has been suggested that cellulose is to be regarded as representing a condition of matter analogous to that of a saline electrolyte in solution, i.e. as a complex of molecular aggregates, and of residues (of monose groups) having distinct and opposite polarities; such a complex is essentially labile and its configuration will change progressively under reaction. The exposition of this view is the subject of a publication by Cross and Bevan (Researches on Cellulose, ii. 1906). The main purpose is to give full effect to the colloidal characteristics of cellulose and its derivatives, with reference to the modern theory of the colloidal state as involving a particular internal equilibrium of amphoteric electrolytes.

The typical cellulose is a white fibrous substance familiar to us in the various forms of bleached cotton. Other fibrous celluloses are equally characteristic as to form and appearance, e.g. bleached flax, hemp, ramie. It is hygroscopic, absorbing 6 to 7% its weight of moisture from the air. When dry, it is an electrical insulator, and has a specific inductive capacity of about 7: when wetted it is a conductor, and manifests electrolytic phenomena.1 It is insoluble in water and in the ordinary solvents; it dissolves, however, in a 40-50% solution of zinc chloride, and in ammoniacal solutions of copper oxide (3% CuO, 15% NH3): from these solutions it is obtained as a highly hydrated, gelatinous precipitate, from the former by dilution or addition of alcohol, from the latter by acidification; these solutions have important industrial application. Projected or drawn into a precipitating solution they may be solidified continuously to threads of various, but controlled dimensions: the regenerated cellulose, now amorphous, in its finer dimensions is known as artificial silk or lustra-cellulose. These forms of cellulose retain the general characters of the original fibrous and “natural” celluloses. In composition they differ somewhat by combination with water (of hydration), which they retain in the air-dry condition. They also further combine with an increased proportion of atmospheric moisture, viz. up to 10-11% of their weight.

Derivatives.—Important derivatives are the esters or ethereal salts of both inorganic and organic acids, cellulose behaving as an alcohol, the highest esters indicating that it reacts as a trihydric alcohol of the formula n[C6H7O2(OH)3]. The nitrates result by the action of concentrated nitric acid, either alone or in the presence of sulphuric acid: the normal dinitrate represents a definite stage in the series of nitrates, and the ester at this point manifests the important property of solubility in various alcoholic solvents, notably ether-alcohol. Such nitrates are the basis of collodion, of artificial silk by the processes of Chardonnet and Lehner, and of celluloid or xylonite. Higher nitrates are also obtainable up to the limit of the trinitrate, which is insoluble in ether or alcohol, but is soluble in nitroglycerin, nitrobenzene and other solvents. These higher nitrates are the basis of the most important modern explosives.

Cellulose reacts directly with acetic anhydride to form low esters; in the presence of sulphuric acid the reaction proceeds to higher limits; the triacetate is soluble in chloroform. The acid sulphuric ester, C6H8O3(SO4H)2, is obtained by the action of sulphuric acid, but its relation to the original cellulose is doubtful. The monobenzoate and dibenzoate are formed by benzoyl chloride reacting on alkali-cellulose (see below). Cellulose xanthates are obtained from carbon bisulphide and alkali-cellulose; these are water soluble derivatives and the basis of “viscose,” and of important industries. Mixed esters—-aceto-sulphate, aceto-benzoate, nitrobenzoyl nitrates, aceto-nitro-sulphates—have also been investigated.

Cellulose (cotton), when treated with a 15-20% caustic soda solution, gives the compound C6H10O5·H2O·2NaOH, alkali-cellulose, the original riband-like form with reticulated walls of the cellulose being transformed into a smooth-walled cylinder. The structural changes in the ultimate fibre determine very considerable changes in the dimensions of fabrics so treated. The reactions and structural changes were investigated by J. Mercer, and are known generally as “mercerization.” In recent years a very large industry in “mercerized” fabrics (cotton) has resulted from the observation that if the shrinkages of the yarns and fabrics be antagonized by mechanical means, a very high lustre is developed.

Similar, but less definite compounds, are formed with the oxides of lead, manganese, barium, iron, aluminium and chromium. These derivatives, which also find industrial applications in the dyeing and printing of fabrics, differ but little in appearance from the original cellulose, and are without influence on its essential characteristics.

Decompositions.—Hydrolysis:—By solution in sulphuric acid followed by dilution and boiling the diluted solution cellulose hydrolyses to fermentable sugars; this reaction is utilized industrially in the manufacture of glucose from rags. Hydrochloric acid produces a friable mass of “hydrocellulose,” probably C12H22O11, insoluble in water, but readily attacked by alkalis, with the production of soluble derivatives; some dextrose is formed in the original reaction. Hydrobromic acid in ethereal solution gives furfurane derivatives. Cold dilute acids have no perceptible action on cellulose. The actions of such acids are an important auxiliary to bleaching, dyeing and printing processes, but they require careful limitation in respect of concentration and temperature. Cellulose is extremely resistant to the action of dilute alkalis: a 1-2% solution of sodium hydrate having little action at temperatures up to 150° hence the use of caustic soda, soda ash and sodium silicate in bleaching processes, i.e. for the elimination of the non-cellulose components of the raw fibres. Oxidation in acid solutions gives compounds classed as “oxycelluloses,” insoluble in water, but more or less soluble in alkalis; continued oxidation gives formic, acetic and carbonic acids. Oxidation in alkaline solution is more easily controlled and limited; solutions of bleaching powder, or more generally of alkaline hydrochlorites, receive industrial application in oxidizing the coloured impurities of the fibre, or residues left after more or less severe alkali treatments, leaving the cellulose practically unaffected. This, however, is obviously a question of conditions: this group of oxidants also oxidize to oxycellulose, and under more severe conditions to acid products, e.g. oxalic and carbonic acids. Certain bacteria also induce decompositions which are resolutions into ultimate products of the lowest molecular dimensions, as hydrogen, carbon dioxide, methane, acetic acid and butyric acid (Omeliansky) (Handb. Techn. Mykologie [F. Lafar] pp. 245-268), but generally the cellulose complex is extremely resistant to the organic ferments. Cellulose burns with a luminous flame to carbon dioxide and water; dry distillation gives a complicated mixture of gaseous and liquid products and a residue of charcoal or pseudo-carbon. Chromic acid in sulphuric acid solutions effects a complete oxidation, i.e. combustion to water and carbonic acid.

Ligno-celluloses.—These compounds have many of the characteristics of the cellulose esters; they are in effect ethereal compounds of cellulose and the quinonoid lignone complex, and the combination resists hydrolysis by weak alkalis or acids. The cellulose varies in amount from 80 to 50%, and the lignone varies inversely as the degree of lignification, that is, from the lignified bast fibre of annuals, of which jute is a type, to the dense tissues of the perennial dicotyledonous woods, typified by the beech. The empirical formula of the lignone complex varies from C19H22O9 (jute) to C26H30O10 (pine wood). In certain reactions the non-cellulose or lignone constituents are selectively converted into soluble derivatives, and may be separated as such from the cellulose which is left; for example, chlorination gives products soluble in sodium sulphite solution, by the combination of unsaturated groups of the lignone with the halogen, while digestion with bisulphite solutions at elevated temperatures (140°-160°) gives soluble sulphonated derivatives. This last reaction is employed industrially in the preparation of cellulose for paper-making from coniferous woods. These reactions are “quantitative” since they depend upon well-defined constitutional features of the lignone complex, and the resolution of the ligno-cellulose takes place with no further change in the lignone than the synthetical combination with the substituting groups. The constituent groups of the lignone specifically reacting are of benzenoid type of the probable form  deduced from the similarity of the chlorinated derivatives to mairogallol, the product of the action of chlorine on pyrogallol in acetic acid solution (A. Hantzsch, Ber. 20, p. 2033). The complex contains methoxy (OCH3) groups. There is also present a residue which is readily broken down by oxidizing agents, and indeed by simple hydrolysis, to acetic acid. Another important group of actual constituents are pentosanes—partially isolated as “wood gum” by solution in alkalis—and furfural derivatives (hydroxy furfurals) derived from these. The actual constitutional relationships of these main groups, as well as the localization of the methoxy groups, are still problematical.

deduced from the similarity of the chlorinated derivatives to mairogallol, the product of the action of chlorine on pyrogallol in acetic acid solution (A. Hantzsch, Ber. 20, p. 2033). The complex contains methoxy (OCH3) groups. There is also present a residue which is readily broken down by oxidizing agents, and indeed by simple hydrolysis, to acetic acid. Another important group of actual constituents are pentosanes—partially isolated as “wood gum” by solution in alkalis—and furfural derivatives (hydroxy furfurals) derived from these. The actual constitutional relationships of these main groups, as well as the localization of the methoxy groups, are still problematical.

Certain colour reactions are characteristic, though they are in some cases reactions of certain constituents invariably present in the natural forms of the ligno-cellulose; which may be removed without affecting the essential character of the lignone complex. Aniline salts generally give a yellow coloration, dimethyl-para-phenylenediamine gives a deep red coloration, phloroglucin in hydrochloric acid gives a crimson coloration. Reactions more definitely characteristic of the lignone are:—ferric ferrocyanide, which is taken up and transformed into Prussian blue throughout the fibre, without affecting its structure, although there may be as much as a 50% gain in weight; iodine in potassium iodide solution gives a deep brown colour due to absorption of the halogen, a reaction which admits of quantitative application, i.e. as a measure of the proportion of ligno-cellulose in a fibrous mixture; nitric acid gives a deep orange yellow coloration; digested with the dilute acid (5-10% HNO3) at 50° the ligno-celluloses are entirely resolved, the lignone complex being attacked and dissolved in the form of nitroso-ketonic acids, which, on continued heating, are finally resolved to oxalic, acetic, formic and carbonic acids.

Derivatives of Ligno-cellulose.—By reaction with chlorine jute yields the derivative C19H18Cl4O9, soluble in alcohol, and in acetic acid; this derivative has the reactions of a quinone chloride. By reaction with sodium sulphite it is converted into a hydroquinone sulphonate of deep purple colour. The reaction of the ligno-celluloses (pine wood) with the bisulphites yields the soluble derivatives of the general formula C26H29O9SO3H (containing two OCH3 groups). Jute reacts with nitric acid in presence of sulphuric acid to form nitrates; and with acetic anhydride to form low acetates. It reacts with alkaline hydrates with structural changes similar to those obtained with cotton; and by the further action of benzoyl chloride and of carbon bisulphide upon the resulting compounds there result the corresponding benzoates and xanthates respectively. But these synthetical derivatives are mixtures of cellulose and lignone derivatives, and so far of merely theoretical interest.

Decompositions of Ligno-cellulose.—In addition to the specific resolutions above described which depend upon the distinctive chemical characters of the cellulose and lignone respectively, the following may be noted: to simple hydrolytic agents the two groups are equally resistant, therefore by boiling with dilute acids or alkalis the groups are attacked pari passu. Weak oxidants may also be used as bleaching agents to remove coloured by-products without seriously attacking the ligno-cellulose, which is obtained in its bleached form. Nitric acid of all strengths effects complete resolution. Chromic acid in dilute solutions combines with the lignone complex, but in presence of hydrolysing acids total oxidation of the lignone is determined. The principal products are oxalic, carbonic, formic and acetic acids. This reaction is an index of constitution. Generally, the lignone is attacked under many conditions and by many reagents which are without action upon cellulose, by virtue of its unsaturated constitution, and its acid and aldehydic residues.

Cuto-cellulose.—A typical cuto-cellulose is the cuticle (peel) of the apple which, when purified by repeated hydrolytic treatment and finally by alcohol and ether, gives a product of the composition C = 75.66%, H = 11.37%, O = 14.97%. Hydrolysis by strong alkalis gives stearo-cutic acid, C28H48O4, and oleo-cutic acid, C14H20O4 (Frémy). Cork is a complex mixture containing various compound celluloses: extraction with alcohol removes certain fatty alcohols and acids, and aromatic derivatives related to tannic acid; the residue is probably a mixture of cellulose, ligno-cellulose, cerin, C20H32O and suberin; the latter yields stearic acid, C18H36O2 and the acid C22H42O3. The cuto-celluloses have been only superficially investigated, and, with the exception of cork, are of but little direct industrial importance.

Industrial Uses of Cellulose.—The applications of cellulose to the necessities of human life, infinitely varied in kind as they are colossal in magnitude, depend upon two groups of qualities or properties, (1) structural, (2) chemical. The manufactures of vegetable textiles and of paper are based upon the fibrous forms of the naturally occurring celluloses, together with such structural qualities as are expressed in the terms strength, elasticity, specific gravity. As regards chemical properties, those which come into play are chiefly the negative quality of resistance to chemical change; this is obviously a primary factor of value in enabling fabrics to withstand wear and tear, contact with atmospheric oxygen and water, and such chemical treatments as laundrying; positive chemical properties are brought into play in the auxiliary processes of dyeing, printing, and the treatment and preparation in connexion with these. Staple textiles of this group are cotton, flax, hemp and jute; other fibres are used in rope-making and brush-making industries. These subjects are treated in special articles under their own headings and in the article Fibres. The course of industrial development in the 19th century has been one of enormous expansion in use and considerable refinement in methods of preparation and manufacture. Efforts to introduce new forms of cellulose have had little result. Rhea or ramie has been a favourite subject of investigation; the industry has been introduced into England, and doubtless its development is only a question of time, as on the continent of Europe the production of rhea yarns is well established, though it is still only a relatively small trade—probably two or three tons a day total production. The paper trade has required to seek new sources of cellulose, in consequence of the enormous expansion of the uses of paper. Important phases of development were: (1) in the period of 1860 to 1870, the introduction of esparto, which has risen to a consumption of 250,000 tons a year in the United Kingdom, at which figure it remains fairly steady; (2) the decade 1870 to 1880, which saw the development of the manufacture of cellulose from coniferous woods, and this industry now furnishes a staple of world-wide consumption, though the industry is necessarily localized in countries where the coniferous woods are available in large quantities. As a development of the paper industry we must mention the manufacture of paper textiles, based upon the production of pulp yarns. Paper pulps are worked into flat strips, which are then rolled into cylindrical form, and by a final twisting process a yarn is produced sufficiently strong to be employed in weaving.

What we may call the special cellulose industries depend upon specific chemical properties of cellulose, partly intrinsic, partly belonging to the derivatives such as the esters. Thus the cellulose nitrates are the bases of our modern high explosives, as well as those now used for military purposes. Their use has been steadily developed and perfected since the middle of the 19th century. The industries in celluloid, xylonite, &c., also depend upon the nitric esters of cellulose, and the plastic state which they assume when treated with solvent liquids, such as alcohol, amyl acetate, camphor and other auxiliaries, in which state they can be readily moulded and fashioned at will. They have taken an important place as structural materials both in useful and artistic applications. The acetates of cellulose have recently been perfected, and are used in coating fine wires for electrical purposes, especially in instrument-making; this use depends upon their electrical properties of high insulation and low inductive capacity. Hydrated forms of cellulose, which result from treatment with various reagents, are the bases of the following industries: vegetable parchment results from the action of sulphuric acid upon cellulose (cotton) in the form of paper, followed by that of water, which precipitates the partially colloidalized cellulose. This industry is carried out on “continuous” machinery, the cellulose, in the form of paper, being treated in rolls. Vulcanized fibre is produced by similar processes, as for instance by treating paper with zinc chloride solvents and cementing together a number of sheets when in the colloidal hydrated state; the goods are exhaustively washed to remove, last traces of soluble electrolytes; this is necessary, as the product is used for electrical insulation. The solvent action of cupro-ammonium is used in treating cellulose goods, cotton and paper, the action being allowed to proceed sufficiently to attack the constituent fibres and convert them into colloidal cupro-ammonium compounds, which are then dried, producing a characteristic green-coloured finish of colloidal cellulose and rendering the goods impervious to water. The important industry of mercerization has been mentioned above; this is carried out on both yarns and cloth of cotton goods chiefly composed of Egyptian cottons. A high lustrous finish is produced, giving the goods very much the appearance of silk.

Of special importance are the more recent developments in the production of artificial fibres of all dimensions, by spinning or drawing the solutions of cellulose or derivatives. Three such processes are in course of evolution, (1) The first is based on the nitrates of cellulose which are dissolved in ether-alcohol, and spun through fine glass jets into air or water, the unit threads being afterwards twisted together to constitute the thread used for weaving (process of Chardonnet and Lehner). These processes were developed in the period 1883 to 1897, at which later date they had assumed serious industrial proportions. (2) The cupro-ammonium solution of cellulose is similarly employed, the solution being spun or drawn into a strong acid bath which instantly regenerates cellulose hydrate in continuous length. (3) Still more recently the “viscose” solution of cellulose, i.e. of the cellulose xanthogenic acid, has been perfected for the production of artificial silk or lustra-cellulose; the alkaline solution of the cellulose derivative being drawn either into concentrated ammonium salt solutions or into acid baths. This product, known as artificial silk, prepared by the three competing processes, was in 1908 an established textile with a total production in Europe of about 5000 tons a year, a quantity which bids fair to be very largely increased by the advent of the viscose process, which will effect a very considerable lowering in the cost of production. The viscose solution of cellulose is also used for a number of industrial effects in connexion with paper-sizing, paper-coating, textile finishes, and the production of book cloth and leather cloth, and, solidified in solid masses, is used in preparing structural solids which can be moulded, turned and fashioned.

For the special literature of cellulose treated from the general point of view of this article, the reader may consult the following works by C.F. Cross and E.J. Bevan: Cellulose (1895, 2nd ed. 1903), Researches on Cellulose, i. (1901), Researches on Cellulose, ii. (1906).

1 C.F. Cross and E.J. Bevan, Jour. Chem. Soc., 1895, 67, p. 449; C.R. Darling, Jour. Faraday Soc. 1904; A. Campbell, Trans. Roy. Soc. 1906.