Boiler, a vessel in which water or other liquid is heated to the boiling point; specifically, the apparatus by which steam is produced from water, as one step in the process whereby the potential energy of coal or other fuel is converted into mechanical work by means of the steam-engine. Boilers of the latter kind must all possess certain essential features, whilst of other qualities that are desirable some may not be altogether compatible with the special conditions under which the boilers are to be worked. Amongst the essentials are a receptacle capable of containing the water and the steam produced by its evaporation, and strong enough continuously to withstand with safety the highest pressure of steam for which the boiler is intended. Another essential is a furnace for burning the fuel, and a further one is the provision of a sufficiency of heating surface for the transmission of the heat produced by the combustion of the fuel to the water which is required to be evaporated. Desirable qualities are that the arrangements of the furnaces should be such that a reasonably perfect combustion of the fuel should be possible, and that the heating surfaces should be capable of transmitting a large proportion of the heat produced to the water so as to obtain a high evaporative efficiency. Further, the design generally should be compact, not too heavy or costly, and such that the cleaning necessary to maintain the evaporative efficiency can be easily effected. It should also be such that the cost of upkeep will be small, and that only an average amount of skill and attention will be required under working conditions. It is for providing these qualities in different degrees according to the special requirements of various circumstances that the very different designs of the various types of boilers have been evolved.

Classes of Boilers.—Boilers generally may be divided into two distinct classes, one comprising those which are generally called “tank” boilers, containing relatively large quantities of water, and the other those which are generally called “water-tube” boilers, in which the water is mainly contained in numerous comparatively small tubes. There are, however, some types of boiler which combine to some extent the properties of both these classes. Each class has its representatives amongst both land and marine boilers. In “tank” boilers the outer shell is wholly or partially cylindrical, this form being one in which the necessary strength can be obtained without the use of a large number of stays. The boilers are generally internally fired, the furnace plates being surrounded with water and forming the most efficient portion of the heating surfaces. On leaving the furnace the products of combustion are led into a chamber and thence through flues or through numerous small tubes which serve to transmit some of the heat of combustion to the water contained in the boiler. In “water-tube” boilers the fire is usually placed under a collection of tubes containing water and forming the major portion of the heating surface of the boiler. Both the fire and the tubes are enclosed in an outer casing of brickwork or other fire-resisting substance. In some forms of water-tube boiler the fire is entirely surrounded by water-tubes and the casing is in no part exposed to the direct action of the fire. In “tank” boilers generally no difficulty is experienced in keeping all the heating surfaces in close contact with water, but in “water-tube” boilers special provision has to be made in the design for maintaining the circulation of water through the tubes. (For “flash” boilers see Motor Vehicles, and for domestic hot-water boilers Heating.)

|

| Fig. 1.—Adamson Joint. |

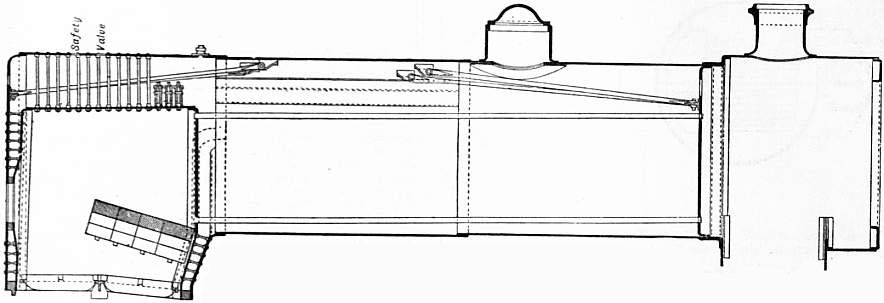

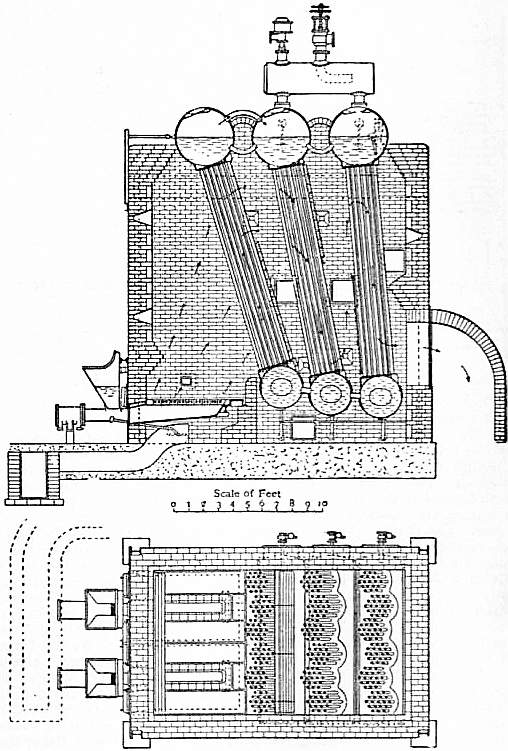

Tank Boilers.—Of large stationary boilers the forms most commonly used are those known as the “Lancashire” boiler, and its modification the “Galloway” boiler. These boilers are made from 26 to 30 ft. long, with diameters from 6½ to Lancashire. 8 ft., and have two cylindrical furnace flues which in the “Lancashire” boiler extend for its whole length (see fig. 3). The working pressure is about 60 ℔ per sq. in. in the older boilers, from 100 ℔ to 120 ℔ per sq. in. in those supplying steam to compound engines, and from 150 to 170 ℔ where triple expansion engines are used. In some cases they have been constructed for a pressure of 200 ℔ per sq. in. The furnace flues are usually made in sections from 3 to 3½ ft. long. Each section consists of one plate bent into a cylindrical form, the longitudinal joint being welded, and is flanged at both ends, the various pieces being joined together by an “Adamson” joint (fig. 1.). It will be seen that these joints do not expose either rivets or double thickness of plate to the action of the fire; they further serve as stiffening rings to prevent collapse of the flue. In most of these boilers the heating surface is increased by fitting in the furnace flues a number of “Galloway” tubes. These are conical tubes, made with a flange at each end, by means of which they are connected to the furnace plate. They are so proportioned that the diameter of the large end of the tube is slightly greater than that of the flange of the small end; this enables them to be readily removed and replaced if necessary. These tubes not only add to the heating surface, but they stiffen the flue, promote circulation of the water in the boiler, and by mixing up the flue gases improve the evaporative efficiency.

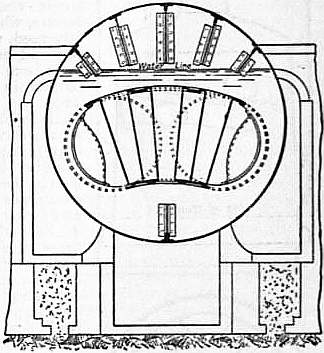

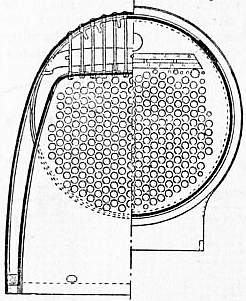

In the “Galloway” boiler the two furnaces extend only for about 9 or 10 ft. into the boiler, and lead into a large chamber or flue in which a number of “Galloway” tubes are fitted, and which extends from the furnace end to the end of the boiler. A cross section of this flue showing the distribution of the Galloway tubes is shown in fig. 2. When boilers less than about 6½ ft. in diameter are needed, a somewhat similar type to the Lancashire boiler is used containing only one furnace. This is called a “Cornish” boiler.

|

| Fig. 2.—Galloway Boiler: Section beyond the Bridge. |

In all three types of boiler the brickwork is constructed to form one central flue passing along the bottom of the boiler and two side flues extending up the side nearly to the water-level. A cross section of the brickwork is shown in fig. 2. The usual arrangement is for the flue gases to be divided as they leave the internal flue; one-half returns along each side flue to the front of the boiler, and the whole then passes downwards into the central flue, travelling under the bottom of the boiler until the gases again reach the back end, where they pass into the chimney. In a few cases the arrangement is reversed, the gases first passing along the bottom flue and returning along the side flues. This latter arrangement, whilst promoting a more rapid circulation of water, has the disadvantage of requiring two dampers, and it is not suitable for those cases in which heavy deposits form on the bottoms of the boilers.

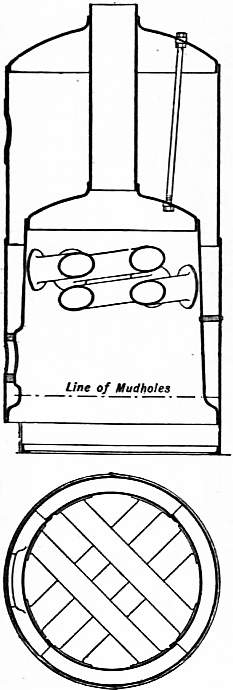

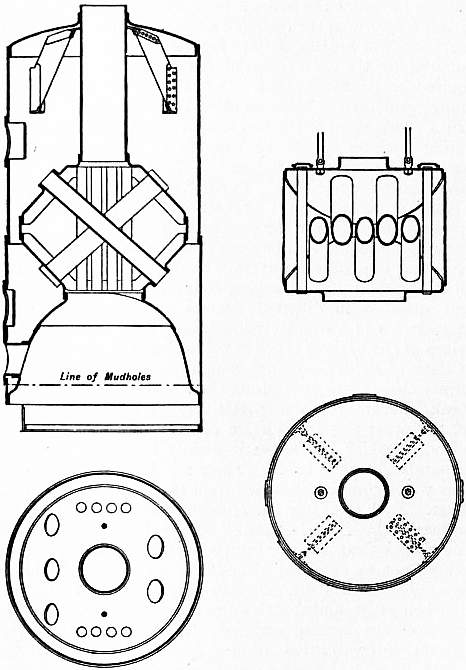

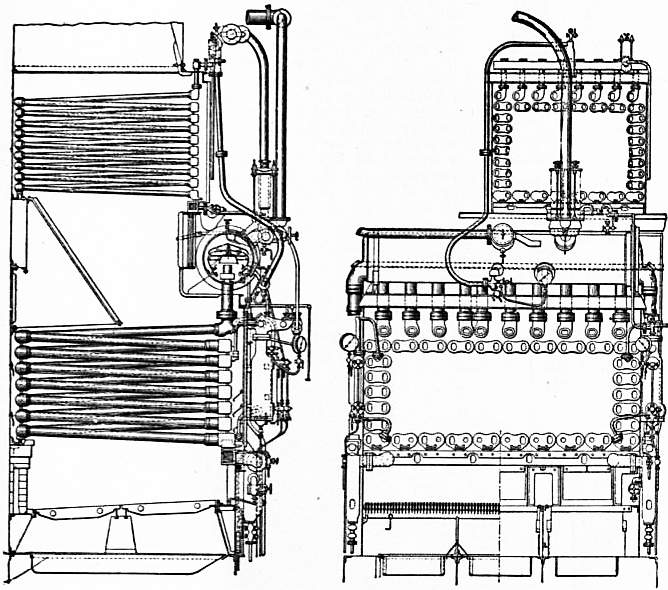

Where floor space is limited and also for small installations, other forms of cylindrical boilers are used, most of them being of the vertical type. That most commonly used is the simple vertical boiler, with a plain vertical fire-box, and an internal Vertical. smoke stack traversing the steam space. The fire-box is made slightly tapering in diameter, the space between it and the shell being filled with water. In all but the small sizes cross tubes are generally fitted. These are made about 9 in. in diameter of 3⁄8-in. plate flanged at each end to enable them to be riveted to the fire-box plates. They are usually fitted with a slight inclination to facilitate water circulation. and a hand-hole closed by a suitable door is provided in the outer shell opposite to each tube for cleaning purposes. A boiler of this kind is illustrated in fig. 4. This form is often used on board ship for auxiliary purposes. Where more heating surface is required than can be obtained in the cross-tube boiler other types of vertical boiler are employed. For instance, in the “Tyne” boiler (fig. 5) the furnace is hemispherical, and the products of combustion are led into an upper combustion chamber traversed by four or more inclined water-tubes of about 9 in. diameter and by several vertical water-tubes of less diameter. In the “Victoria” boiler made by Messrs Clarke, Chapman & Co., and illustrated in fig. 6, the furnace is hemispherical; the furnace gases are led to an internal combustion chamber, and thence through numerous horizontal smoke-tubes to a smoke-box placed on the side of the boiler. In the somewhat similar boiler known as the “Cochran,” the combustion chamber is made with a “dry” back. Instead of a water space at the back of the chamber, doors lined with firebrick are fitted. These give easy access to the tube ends.

|

| Fig. 3.—Lancashire Boiler (Messrs Tinker, Ltd.). |

|

| Fig. 4.—Simple Vertical Boiler. |

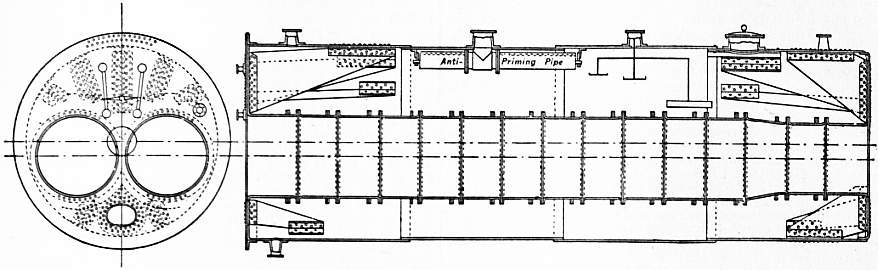

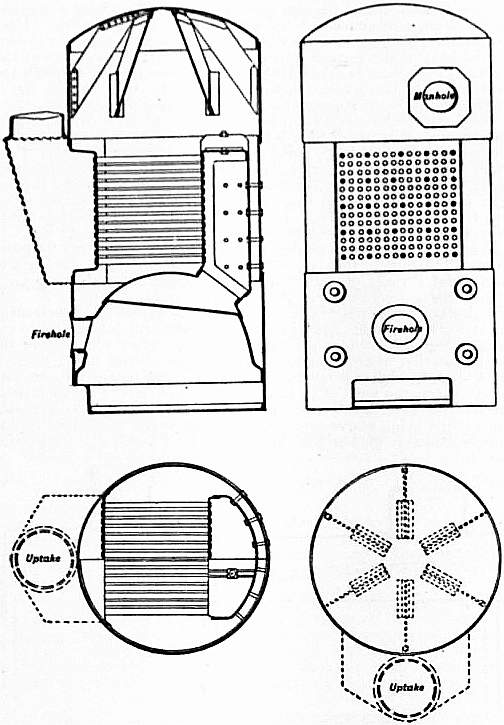

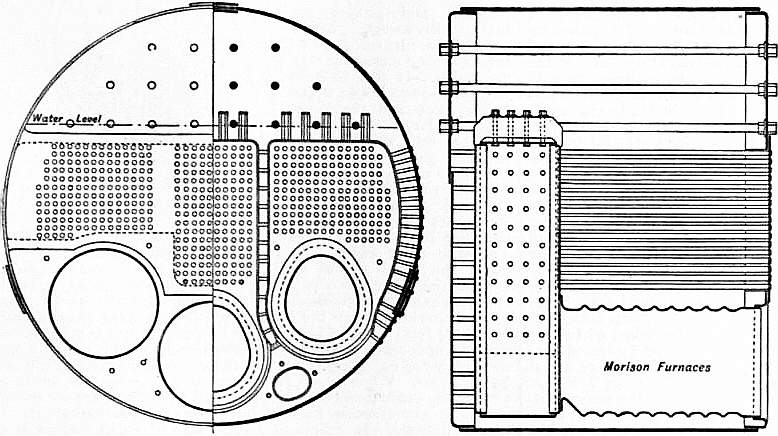

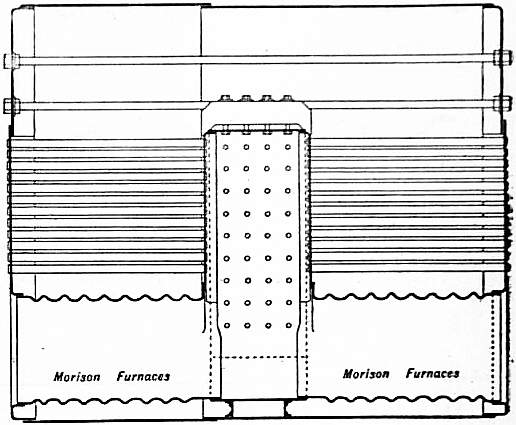

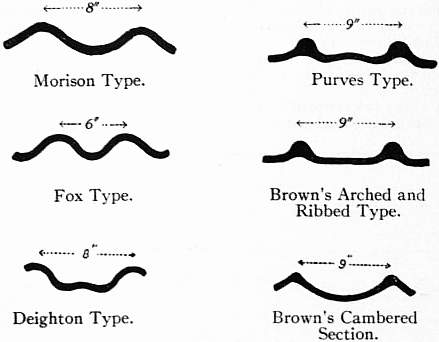

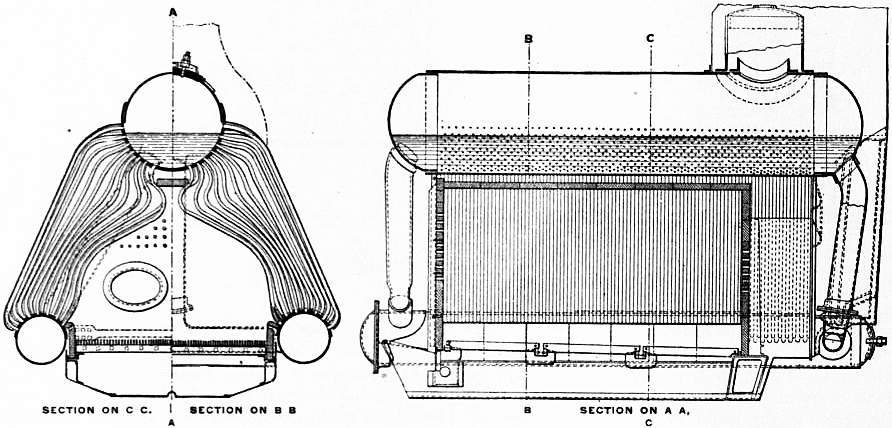

The cylindrical multitubular return tube boiler is in almost universal use in merchant steamers. It is made in various sizes ranging up to 17 ft. in diameter, the usual working pressure being from 160 to 200 ℔ Marine. per sq. in., although in some few cases pressures of 265 ℔ per sq. in. are in use. These boilers are of two types, double- and single-ended. In single-ended boilers, which are those most generally used, the furnaces are fitted at one end only and vary in number from one in the smallest boiler to four in the largest. Three furnaces are the most usual practice. Each furnace generally has its own separate combustion chamber. In four furnace boilers, however, one chamber is sometimes made common to the two middle furnaces, and sometimes one chamber is fitted to each pair of side furnaces. In double-ended boilers furnaces are fitted at each end. In some cases each furnace has a separate combustion chamber, but more usually one chamber is made to serve for two furnaces, one at each end of the boiler. The two types of boilers are shown in figs. 7 and 8, which illustrate boilers made by Messrs D. Rowan & Co. of Glasgow, and which may be taken as representing good modern practice. The furnaces used in the smaller sizes are often of the plain cylindrical type, the thickness of plate varying from 3⁄8 in. up to ¾ in. according to the diameter of the furnace and the working pressure. Occasionally furnaces with “Adamson” joints similar to those used in Lancashire boilers are employed, but for large furnaces and for high pressures corrugated or ribbed furnaces are usually adopted. Sketches of the sections of these are shown in fig. 9. The sections of the Morison, Fox and Deighton types are made from plates originally rolled of a uniform thickness, made into a cylindrical form with a welded longitudinal joint and then corrugated, the only difference between them being in the shapes of the corrugations. In the other three types the plates from which the furnaces are made are rolled with ribs or thickened portions at distances of 9 in. These furnaces are stronger to resist collapse than plain furnaces of the same thickness, and accommodate themselves more readily to changes of temperature.

|

| Fig. 5.—Vertical Boiler with Water-tubes (the “Tyne,” by Messrs Clarke, Chapman & Co.). |

There are two distinct types of connexion between the furnaces and the combustion chambers. In one, shown in fig. 8, the furnace is flanged at the crown portion for riveting to the tube plate, and the lower part of the furnace is riveted to the “wrapper” or side plate of the combustion chamber. In the other type, shown in fig. 7, and known generally as the “Gourlay back end,” the end of the furnace is contracted into an oval conical form, and is then flanged outwards round the whole of its circumference. The tube plate is made to extend to the bottom of the combustion chamber, and the furnace is riveted to the tube plate. The advantage of the Gourlay back end is that in case of accident to the furnace it can be removed from the boiler and be replaced by one of the same design without disturbing the end plates, which is not possible with the other design. The Gourlay back end, however, is not so stiff as the other, and more longitudinal stays are required in the boiler.

|

| Fig. 6.—Vertical Boiler with internal combustion chamber (the “Victoria,” by Messrs Clarke, Chapman & Co.). |

|

| Fig. 7.—Single-ended Marine Boiler. |

The flat sides and backs of the combustion chambers are stayed either to one another or to the shell of the boiler by numerous screw stays which are screwed through the two plates they connect, and which are nearly always fitted with nuts inside the combustion chambers. The tops of the chambers are usually stayed by strong girders resting upon the tube plates and chamber back plates. In a few cases, however, they are stayed by vertical stays attached to T bars riveted to the boiler shell. A few boilers are made in which the chamber tops are strengthened by heavy transverse girder plates. The end plates of the boiler in the steam space and below the combustion chambers are stayed by longitudinal stays passing through the whole length of the boiler and secured by double nuts at each end. The tube plates are strengthened by stay tubes screwed into them.

Where natural or chimney draught is used the tubes are generally made 3 or 3¼ in. outside diameter and are rarely more than 7 ft. long, but where “forced” draught is employed they are usually made 2½ in. diameter and 8 to 8½ ft. long. A clear space of 1¼ in. between the tubes is almost always arranged for, irrespective of size of tubes.

|

| Fig. 8.—Double-ended Marine Boiler. |

Stay tubes are screwed at both ends, the threads of the two ends being continuous so that they can be screwed into both tube plates; occasionally nuts are fitted to the front ends. The stay tubes are expanded into the plates and then beaded over.

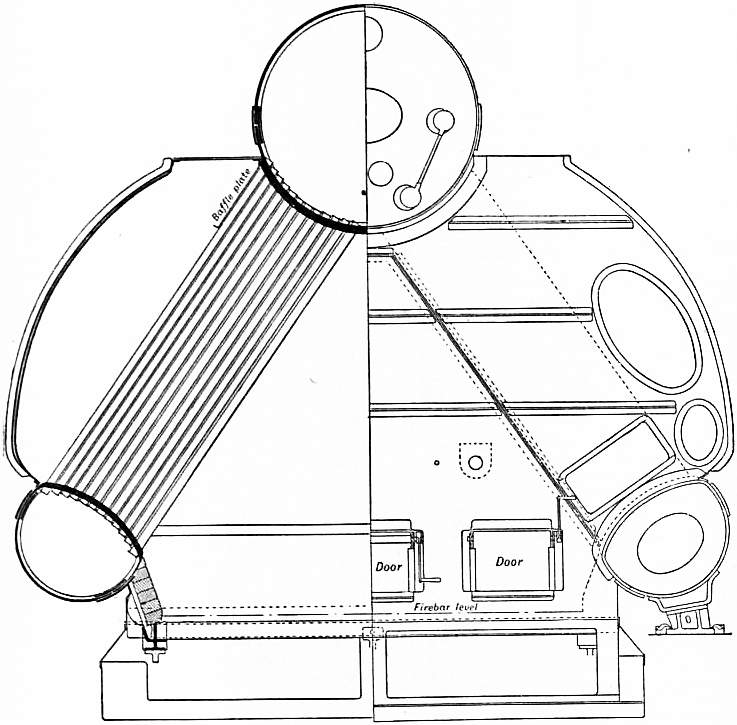

The locomotive boiler consists of a cylindrical barrel attached to a portion containing the fire-box, which is nearly rectangular both in horizontal and vertical section. The fire-box sides are stayed to the fire-box shell by numerous stays about Locomotive. 1 in. in diameter, usually pitched 4 in. apart both vertically and horizontally. The top of the fire-box in small boilers is stayed by means of girder stays running longitudinally and supported at the ends upon the tube plate and the opposite fire-box plate. In some boilers the girders are partly supported by slings from the crown of the boiler. In larger boilers the crown of the boiler above the fire-box is made flat and the fire-box crown is supported by vertical stays connecting it with the shell crown. Provision is generally made for the expansion of the tube plate, which is of copper, by allowing the two or three cross rows of stays nearest the tube plate to have freedom of motion upwards but not downwards. The ordinary tubes are usually 1¾ in. diameter. The fire-bars are generally, though not always, made to slope downwards away from the fire door, and just below the lowest tubes a fire-bridge or baffle is fitted, extending about half-way from the tube plate to the fire-door side of the fire-box. In some cases water-tubes are fitted, extending right across the fire-box. In a boiler for the London & South-Western Railway Co., having a grate area of 31.5 sq. ft. and a total heating surface of 2727 sq. ft., there are 112 water-tubes each 2¾ in. diameter. These are arranged in two clusters, each containing 56, one set being placed above the fire-bridge, and the other set nearer the fire-door end of the boiler. The water-tubes are of seamless steel, and are expanded into the fire-box side plates. In way of these tubes the outer shell side plates are supported by stay bars passing right through the water-tubes. The usual pressure of locomotive boilers is about 175 ℔ to 200 ℔ per sq. in.

|

| Fig. 9. |

A good example of an express locomotive boiler is shown in fig. 10. In this case the grate area is 30.9 sq. ft. and the heating surface 2500 sq. ft. The barrel is 5 ft. 6 in. diameter, 16 ft. long between tube plates. The fire-box crown is stayed by vertical stays extending to the shell crown, except for the three rows of stays nearest the tube plates. These are supported by cross girders resting upon brackets secured to the outer shell.

|

| Fig. 10.—Express Locomotive Boiler, with widened fire-box (Great Northern Railway, England). |

|

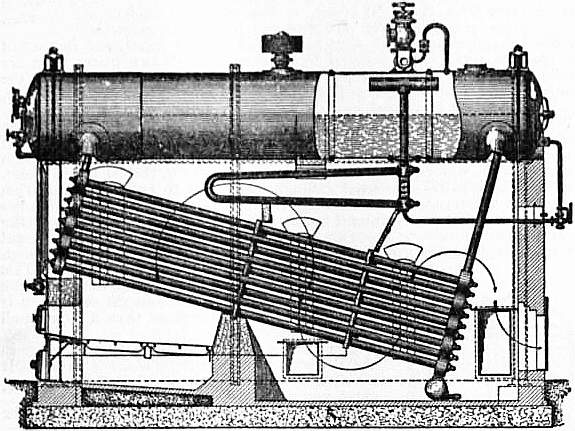

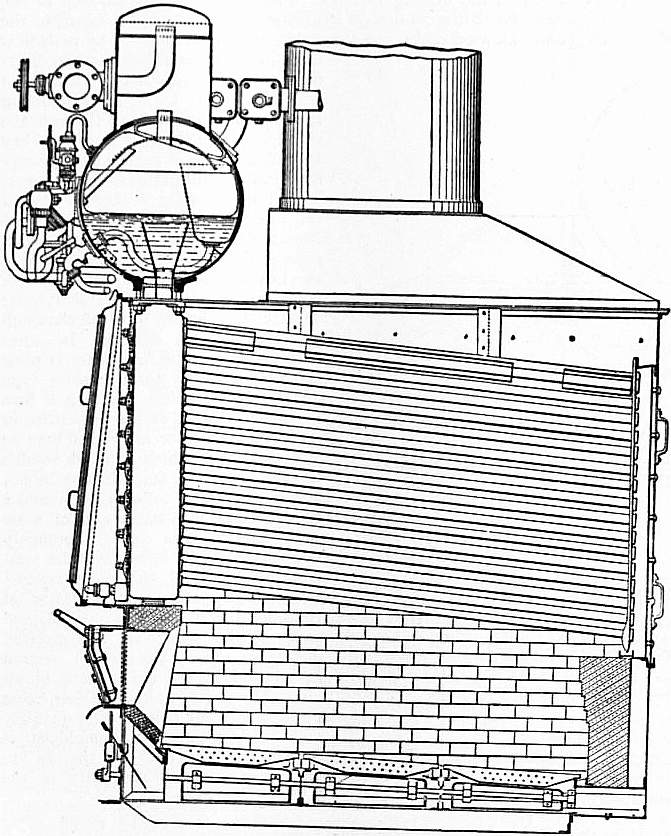

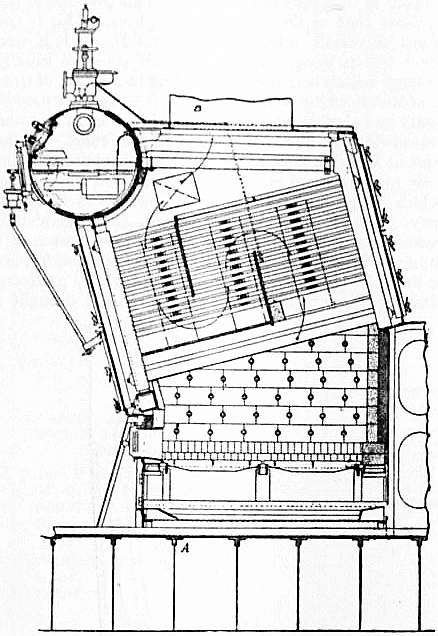

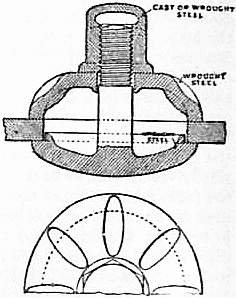

Water-Tube Boilers.—The “Babcock & Wilcox” boiler, as fitted for land purposes, and illustrated in fig. 11, consists of a horizontal cylinder forming a steam chest, having dished ends and two specially constructed cross-boxes riveted to the Babcock and Wilcox stationary. bottom. Under the cylinder is placed a sloping nest of tubes, under the upper end of which is the fire. The sides and back of the boiler are enclosed in brickwork up to the height of the centre of the horizontal cylinder and the front is fitted with an iron casing lined with brick at the lower part. Suitable brickwork baffles are arranged between the tubes themselves, and between the nests of tubes and the cylinder, to ensure a proper circulation of the products of combustion, which are made to pass between the tubes three times. The nest of tubes consists of several separate elements, each formed by a front and back header made of wrought steel of sinuous form connected by a number of tubes. The upper ends of the front headers are connected by short tubes to the front cross-box of the horizontal cylinder, the lower ends being closed. The upper ends of the back headers are connected by longer pipes to the back cross-box, and their lower ends by short pipes to a horizontal mud drum to which a blow-off cock and pipe are attached. The headers are furnished with holes on two opposite sides; those on one side form the means of connexion between the headers and tubes, and the others allow access for fixing the tubes in position and cleaning. The outer holes are oval, and closed by special fittings shown in fig. 18, the watertightness of the joints being secured by the outer cover plates. The holes being oval, the inside fitting can be placed in position from outside, and it is so made as to cover the opening and prevent any great outrush of steam or water should the bolt break. Any desired working pressure can be provided for in these boilers; in some special cases it rises as high as 500 ℔ per sq. in., but a more usual pressure is 180 ℔ Like all water-tube boilers, they require to be frequently cleaned if impure feed-water is used, but the straightness of their tubes enables their condition to be ascertained at any time when the boiler is out of use, and any accumulation of scale to be removed. The superheaters, which are frequently fitted, consist of two cross-boxes or headers placed transversely under the cylindrical drum and connected by numerous C-shaped tubes. They are situated between the tubes and the steam-chest, and are exposed to the heat of the furnace gases after their first passage across the tubes. The steam is taken by an internal pipe passing through the bottom of the drum into the upper cross-box, then through the C tubes into the lower box, and thence to the steam pipe. When steam is being raised, the superheater is flooded with water, which is drained out through a blow-off pipe before communication is opened with the steam-pipe. In large boilers of this type, two steam-chests are placed side by side connected together by two cross steam pipes and by the mud drum. Each, however, has its own separate feed supply. The largest boiler made has two steam chests 4½ ft. diameter by 25½ ft. long, a grate surface of 85 sq. ft., and a total heating surface of 6182 sq. ft.

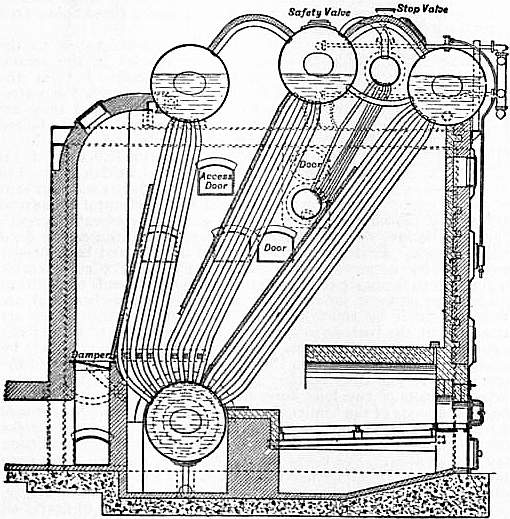

Another type of water-tube boiler in use for stationary purposes is the “Stirling” (fig. 12). This boiler consists of four or five horizontal drums, of which the three upper form the steam-space, and the one or two lower contain water. Stirling. The lower drums, where two are fitted, are connected to each other at about the middle of their height by horizontal tubes, and to the upper drums by numerous nearly vertical tubes which form the major portion of the heating surfaces. The central upper drum is at a slightly higher level than the others, and communicates with that nearest the back of the boiler by a set of curved tubes entirely above the water-level, and with the front drum by two sets—the upper one being above and the lower below the water-level. The whole boiler is enclosed in brickwork, into which the supporting columns and girders are built. Brickwork baffles compel the furnace gases to take specified courses among the tubes. It will be seen that the space between the boiler front and the tubes form a large combustion chamber into which all the furnace gases must pass before they enter the spaces between the tubes; in this chamber a baffle-bridge is sometimes built. Another chamber is formed between the first and second sets of tubes. The feed-water enters the back upper drum, and must pass down the third set of tubes into the lower drum before it reaches the other parts of the boiler. Thus the coldest water is always where the temperature of the furnace gases is lowest; and as the current through the lower drum is slight, the solid matters separated from the feed-water while its temperature is being raised have an opportunity of settling to the bottom of this drum, where the heating is not great and where therefore their presence will not be injurious. When superheaters are required, they are made of two drums connected by numerous small tubes, and are somewhat similar in construction to the boiler proper. The superheater is placed between the first and second sets of tubes, where it is exposed to the furnace gases before too much heat has been taken from them. Arrangements are provided for flooding the superheater while steam is being raised, and for draining it before the steam is passed through it.

|

| Fig. 11.—Babcock & Wilcox Water-tube Boiler fitted with Superheaters. |

A somewhat similar boiler is made by Messrs. Clarke, Chapman & Co., and is known as the “Woodeson” boiler (fig. 13). It consists of three upper drums placed side by side connected together by numerous short tubes, some above and some Woodeson. below the water-level, and of three smaller lower drums also connected by short cross tubes. The upper and lower drums are connected by numerous nearly vertical straight tubes. The whole is enclosed in firebrick casing. The design permits of the insides of all the tubes being readily inspected, and also of any tube being taken out and renewed without displacing any other part of the boiler.

|

| Fig. 12.—Stirling Water-tube Boiler. |

The earliest form of water-tube boiler which came into general use in the British navy is the Belleville. Two views of this boiler are shown in fig. 14. It is composed of two parts, the boiler proper and the “economizer.” Each of these consists of Belleville. several sets of elements placed side by side; those of the boiler proper are situated immediately over the fire, and those of the economizer in the uptake above the boiler, the intervening space being designed to act as a combustion chamber. Each element is constructed of a number of straight tubes connected at their ends by means of screwed joints to junction-boxes which are made of malleable cast iron. These are arranged vertically over one another, and except in the case of the upper and lower ones at the front of the boiler, each connects the upper end of one tube with the lower end of the next tube of the element. The boxes at the back of the boiler are all close-ended, but those at the front are provided with a small oval hole, opposite to each tube end, closed by an internal door with bolt and cross-bar; the purpose of these openings is to permit the inside of the tubes to be examined and cleaned. The lower front box of each element of the boiler proper is connected to a horizontal cross-tube of square section, called a “feed-collector,” which extends the whole width of the boiler. When the boiler is not in use, any element can be readily disconnected and a spare one inserted. The lower part of the steam-chest is connected to the feed-collector by vertical pipes at each end of the boiler, and prolongations of these pipes below the level of the feed-collector form closed pockets for the collection of sediment. The tubes are made of seamless steel. They are generally about 4½ in. in external diameter: the two lower rows are 3⁄8 in. thick, the next two rows 5⁄16 and the remainder about 1⁄5 in. The construction of the economizer is similar to that of the boiler proper, but the tubes are shorter and smaller, being generally about 2¾ in. in diameter. The lower boxes of the economizer elements are connected to a horizontal feed pipe which is kept supplied with water by a feed-pumping engine, and the upper boxes are connected to another horizontal pipe from which the heated feed-water is taken into the steam-chest. Both the boiler proper and the economizer are enclosed in a casing which is formed of two thicknesses of thin iron separated by non-conducting material and lined with firebrick at the part between the fire-bar level and the lower rows of tubes. Along the front of the boiler, above the level of the firing-doors, there is a small tube having several nozzles directed across the fire-grate, and supplied with compressed air at a pressure of about 10 ℔ per sq. in. In this way not only is additional air supplied, but the gases issuing from the fire are stirred up and mixed, their combustion being thereby facilitated before they pass into the spaces between the tubes. A similar air-tube is provided for the space between the boiler proper and the economizer. Any water suspended in the steam is separated in a special separator fitted in the main steam-pipe, and the steam is further dried by passing through a reducing-valve, which ensures a steady pressure on the engine side of the valve, notwithstanding fluctuations of pressure in the boiler. The boiler pressure is usually maintained at about 50 ℔ per sq. in. in excess of that at which the engines are working, the excess forming a reservoir of energy to provide for irregular firing or feeding.

|

| Fig. 13.—Woodeson Boiler (Messrs Clarke, Chapman & Co.). |

|

| Fig. 14.—Belleville Boiler. |

Another type of large-tube boiler which has been used in the British and in other navies is the “Niclausse,” shown in fig. 15. It is also in use on land in several electric-light installations. It consists of a horizontal steam-chest under Niclausse. which is placed a number of elements arranged side by side over the fire, the whole being enclosed in an iron casing lined with firebrick where it is exposed to the direct action of the fire. Each element consists of a header of rectangular cross-section, fitted with two rows of inclined close-ended tubes, which slope downwards towards the back of the boiler with an inclination of 6° to the horizontal. The headers are usually of malleable cast iron with diaphragms cast in them, but sometimes steel has been employed, the bottoms being closed by a riveted steel plate, and the diaphragms being made of the same material. The headers are bolted to socket-pieces which are riveted to the bottom of the steam-chest, so that any element may be easily removed. The tube-holes are accurately bored, at an angle to suit the inclination of the tubes, through both the front and back of the headers and through the diaphragm, those in the header walls being slightly conical. The tubes themselves, which are made of seamless steel, are of peculiar construction. The lower or back ends are reduced in diameter and screwed and fitted with cap-nuts which entirely close them. The front ends are thickened by being upset, and the parts where they fit into the header walls and in the diaphragm are carefully turned to gauge. The upper and lower parts of the tubes between these fitting portions are then cut away, the side portions only being retained, and the end is termed a “lanterne.” A small water-circulating tube of thin sheet steel, fitted inside each generating tube, is open at the lower end, and at the other is secured to a smaller “lanterne,” which, however, only extends from the front of the header to the diaphragm. This smaller “lanterne” closes the front end of the generating tube. The whole arrangement is such that when the tubes are in place only the small inner circulating tubes communicate with the space between the front of the header and the diaphragm, while the annular spaces in the generating tubes around the water-circulating tubes communicate only with the space between the diaphragm and the back of the header. The steam formed in the tubes escapes from them into this back space, through which it rises into the steam-chest, whilst the space in the front of the header always contains a down-current of water supplying the inner circulating tubes. The tubes are maintained in position by cross-bars, each secured by one stud-bolt screwed into the header front wall, and each serving to fix two tubes. The products of combustion ascend directly from the fire amongst the tubes, and the combustion is rendered more complete by the introduction of jets of high-pressure air immediately over the fire, as in the “Belleville” boiler.

The “Dürr” boiler, in use in several vessels in the German navy, and in a few vessels of the British navy, in some respects resembles the “Niclausse.” The separate headers of the latter, however, are replaced by one large water-chamber Dürr. formed of steel plates with welded joints, and instead of the tubes being secured by “lanternes” to two plates they are secured to the inner plate only by conical joints, the holes in the outer plate being closed by small round doors fitted from the inside. In fixing the tubes each is separately forced into its position by means of a small portable hydraulic jack. The lower ends of the caps are closed by cap-nuts made of a special heat-resisting alloy of copper and manganese. Circulation is provided for by a diaphragm in the water-chamber and by inner tubes as in the Niclausse boiler. Baffle plates are fitted amongst the tubes to ensure a circulation of the furnace gases amongst them. Above the main set of tubes is a smaller set arranged horizontally, and connected directly to the steam receiver. These are fitted with internal tubes, and an internal diaphragm is provided so that steam from the chest circulates through these tubes on its way to the stop-valves. This supplementary set of tubes is intended to serve as a superheater, but the amount of surface is not sufficient to obtain more than a very small amount of superheat.

The Yarrow boiler (fig. 16) is largely in use in the British and also in several other navies. It consists of a large cylindrical steam chest and two lower water-chambers, Yarrow. connected by numerous straight tubes. In the boilers for large vessels all the tubes are of 1¾ in. external diameter, but in the large express boilers the two rows nearest to the fire on each side are of 1¼ in. and the remainder of 1 in. diameter. They are arranged with their centres forming equilateral triangles, and are spaced so that they can be cleaned externally both from the front of the boiler and also cross-ways in two directions. In some boilers the lower part of the steam-chest is connected with the water-chambers by large pipes outside the casings with the view of improving the circulation.

The largest size of single-ended large tube boiler in use has a steam drum 4 ft. 2 in. diameter, a grate area of 73.5 sq. ft. and 3750 sq. ft. of heating surface, but much larger double-ended boilers have been made, these being fired from both ends.

In most of the boilers made, access to the inside is obtained by manholes in the steam-chest and water-chamber ends, but in the smaller sizes fitted in torpedo boats the water-chambers are too small for this, and they are each arranged in two parts connected by a bolted joint, which makes all the tube ends accessible.

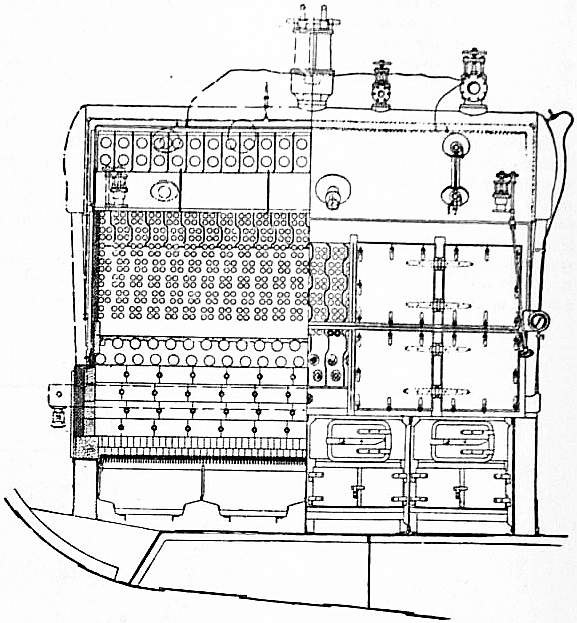

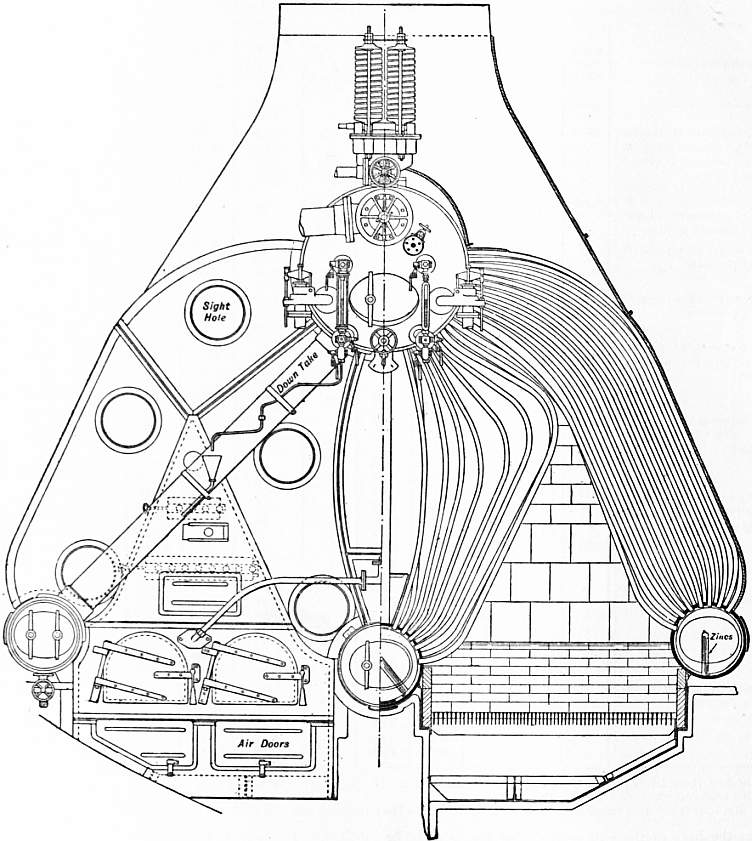

The Babcock & Wilcox marine boiler (fig. 17) is much used in the American and British navies, and it has also been used in several yachts and merchant steamers. It consists of a horizontal cylindrical steam-chest placed transversely over a group of elements, beneath which is the fire, the whole being enclosed in an iron casing lined with firebrick. Each element consists of a front and back header connected by numerous water-tubes which have a considerable inclination to facilitate the circulation. The upper ends of the front headers are situated immediately under the steam-chest and are connected to it by short nipples; by a similar means they are connected at the bottom to a pipe of square section which extends across the width of the boiler. Additional connexions are made by nearly vertical tubes between this cross-pipe and the bottom of the steam-chest. The back headers are each connected at their upper ends by means of two long horizontal tubes with the steam-chest, the bottom ends of the headers being closed. The headers are made of wrought steel, and except the outer pairs, which are flat on the outer portions, they are sinuous on both sides, the sinuosities fitting into one another. The tubes are of two sizes, the two lower rows and the return tubes between the back headers and steam-chest being 315⁄16 in. outside diameter, and the remaining tubes 113⁄16 in. The small tubes are arranged in groups of two or four to nearly all of the sinuosities of the headers, the purpose of this arrangement being to give opportunities for the furnace gases to become well mixed together, and to ensure their contact with the heating surfaces. Access for securing the tubes in the headers is provided by a hole formed on the other side of the header opposite each of the tubes, where they are grouped in fours, and by one larger hole opposite each group of two tubes. The larger holes are oval, and are closed by fittings similar to those used in the land boiler (fig. 18). The smaller holes are conical, with the larger diameter on the inside, and are closed by special conical fittings: the conical portion and bolt are one forging, and the nut is close-ended. In case of the breakage of the bolt, the fitting would be retained in place by the steam-pressure. A set of firebrick baffles is placed so as to cover rather more than half of the spaces between the upper of the two bottom rows of large tubes, and another set of baffles covers about two-thirds of the spaces between the upper small tubes. Vertical baffles are also built between the smaller tubes, as shown in the longitudinal section. These baffles compel the products of combustion to circulate among the tubes in the direction shown by the arrows. Experience has shown that this arrangement gives a better evaporative efficiency than where the furnace gases are allowed to pass unbaffled straight up between the tubes. The boilers are usually fitted in pairs placed back to back, and one side of each is always made accessible. On this side the casing is provided with numerous small doors, through any of which a steam jet can be inserted for the purpose of sweeping the tubes.

|

| Fig. 15.—Niclausse Boiler—transverse section. |

A class of water-tube boilers largely in use in torpedo-boat destroyers and cruisers, where the maximum of power is required in proportion to the total weight of the installation, is generally known as express boilers. In these the tubes Express boilers. are made of smaller diameter than those used in the boilers already described, and the boilers are designed to admit of a high rate of combustion of fuel obtained by a high degree of “forced draught.” Of these express boilers the Yarrow is of similar construction to the large tube Yarrow boiler already described with the exception that the tubes are smaller in diameter and much more closely arranged.

In the Normand boiler (fig. 19) there are three chambers as in the Yarrow, connected together by a large number of bent tubes which form the heating surface, and also connected at each end by large outside circulating tubes. The two outer rows Normand. of heating tubes on each side are arranged to touch one another to nearly their whole length so as to form a “water-wall” for the protection of the outer casing. They enter the steam-chest at about the water-level. The two inner rows of tubes, which are bent to the form shown in the figure, also form a water-wall for the larger portion of the length of the boiler, and thus compel the products of combustion to pass in a definite course amongst all the tubes. In the Blechynden and White-Foster boilers there are also three chambers connected by bent tubes, the curvature being so arranged that in the former boiler any of the tubes can be taken out of the boiler through small doors provided in the upper part of the steam-chest, and in the White-Foster boiler they can be taken out through the manhole in the end of the steam-chest.

In the Reed boiler the tubes are longer and more curved than in the Normand boiler, and there are no “water-walls,” the products of combustion passing from the fire-grate amongst all the tubes direct to the chimney. The special feature of Reed. the boiler is that each tube, instead of being expanded into the tube plate, is fitted at each end with specially designed screw and nut connexions to enable them to be quickly taken out and replaced if necessary. At their lower ends the tubes are reduced in diameter to enable smaller chambers to be used than would otherwise be necessary. Provision is made for access to the lower tube ends by means of numerous doors in the water-chambers. Access to the top ends is obtained in the steam-chest.

Messrs John I. Thornycroft & Co. make two forms of express boiler. One called the Thornycroft boiler consists of three chambers connected by tubes which are straight for the major portion of their length but bent at each end to enable Thornycroft. them to enter the steam- and water-chambers normally. The outer rows of tubes form “water-walls” at their lower parts, but permit the passage of the gases between them at their upper ends. Similarly the inner rows form “water-walls” at their upper parts, but are open at the lower ends. The products of combustion are thus compelled to pass over the whole of the heating surfaces. The fire-rows of tubes in this boiler are made 13⁄8 in. outside diameter and the remainder are made 11⁄8 in. diameter. Large outside circulating pipes are provided at the front end of the boiler.

In the other type of boiler, known as the Thornycroft-Schulz boiler (fig. 20), there are four chambers, and the fire-grate is arranged in two separate portions. The two outermost rows of tubes on each side are arranged to form water-walls at Thornycroft-Schulz. their lower part, and permit the gases to pass between them at the upper part. The rows nearest the fires are arranged similarly to those in the Thornycroft boiler. Circulation in the outer sets of tubes is arranged for by outer circulating pipes of large diameter connecting the steam- and water-chambers. For the middle water-chamber several nearly vertical down-comers are provided in the centre of the boiler. Boilers of this type are extensively used in the British and German navies.

Material of Boilers.—In ordinary land boilers and in marine boilers of all types the plates and stays are almost invariably made of mild steel. For the shell plates and for long stays, a quality having a tensile strength ranging from 28 to 32 tons per sq. in. is usually employed, and for furnaces and flues, for plates which have to be flanged, and for short-screwed stays, a somewhat softer steel with a strength ranging from 26 to 30 tons per sq. in. is used. The tubes of ordinary land and marine boilers are usually made of lap-welded wrought iron. In water-tube boilers for naval purposes seamless steel tubes are invariably used. In locomotive boilers the shells are generally of mild steel, the fire-box plates of copper (in America of steel), the fire-box side stays of copper or special bronze, and other stays of steel. The tubes are usually of brass with a composition either of two parts by weight of copper to one of zinc or 70% copper, 30% zinc; sometimes, however, copper tubes and occasionally steel tubes are used. Where water tubes are used they are made of seamless steel.

Boiler Accessories.—All boilers must be provided with certain mountings and accessories. The water-level in them must be kept above the highest part of the heating surfaces. In some land boilers, and in some of the water-tube boilers used on shipboard, the feeding is automatically regulated by mechanism actuated by a float, but in these cases means of regulating the feed-supply by hand are also provided. In most boilers hand regulation only is relied upon. The actual level of water in the boiler is ascertained by a glass water-gauge, which consists of a glass tube and three cocks, two communicating directly with the boiler, one above and one below the desired water-level, and the third acting as a blow-out for cleaning the gauge and for testing its working. Three small try-cocks are also fitted, one just at, one above, and one below the proper water-level. The feeding of the boiler is sometimes performed by a pump driven from the main engine, sometimes by an independent steam-pump, and sometimes by means of an injector. The feed-water is admitted by a “check-valve,” the lift of which is regulated by a screw and hand-wheel, and which when the feed-pump is not working is kept on its seating by the boiler pressure.

|

| Fig. 16.—Yarrow Water-tube Boiler. |

Every boiler is in addition supplied with a steam-gauge to indicate the steam-pressure, with a stop-valve for regulating the admission of steam to the steam-pipes, and with one or two safety-valves. These last in stationary boilers usually consist of valves kept in their seats against the steam-pressure in the boiler by levers carrying weights, but in marine and locomotive boilers the valves are kept closed by means of steel springs. One at least of the safety-valves is fitted with easing gear by which it can be lifted at any time for blowing off the steam. Blow-out cocks are fitted for emptying the boiler.

Openings must always be made in boilers for access for cleaning and examination. When these are large enough to allow a man to enter the boiler they are termed man-holes. They are usually made oval, as this shape permits the doors by which they are closed to be placed on the inside so that the pressure upon them tends to keep them shut. The doors are held in place by one or two bolts, secured to cross-bars or “dogs” outside the boiler. It is important in making these doors that they should fit the holes so accurately that the jointing material cannot be forced out of its proper position. In the few cases where doors are fitted outside a boiler, so that the steam-pressure tends to open them, they are always secured by several bolts so that the breakage of one bolt will not allow the door to be forced off.

Water-softening.—Seeing that the impurities contained in the feed-water are not evaporated in the steam they become concentrated in the boiler water. Most of them become precipitated in the boiler either in the form of mud or else as scale which forms on the heating surfaces. Some of the mud and such of the impurities as remain soluble may be removed by means of the blow-off cocks, but the scale can only be removed by periodical cleaning. Incrustations on the heating surface not only lessen the efficiency of the boiler by obstructing the transmission of heat through the plates and tubes, but if excessive they become a source of considerable danger by permitting the plates to become overheated and thereby weakened. When the feed-water is very impure, therefore, the boilers used are those which permit of very easy cleaning, such as the Lancashire, Galloway and Cornish types, to the exclusion of multitubular or water-tube boilers in which thorough cleaning is more difficult. In other cases, however, the feed-water is purified by passing it through some type of “softener” before pumping it into the boiler. Most of the impurities in ordinary feed-water are either lime or magnesia salts, which although soluble in cold water are much less so in hot water. In the “softener” measured quantities of feed-water and of some chemical reagents are thoroughly mixed and at the same time the temperature is raised either by exhaust steam or by other means. Most of the impurity is thus precipitated, and some of the remainder is converted into more soluble salts which remain in solution in the boiler until blown out. The water is filtered before being pumped into the boiler. The quantity and kind of chemical employed is determined according to the nature and amount of the impurity in the “hard” feed-water.

Thermal Storage.—In some cases where the work required is very intermittent, “thermal storage” is employed. Above the boiler a large cylindrical storage vessel is placed, having sufficient capacity to contain enough feed-water to supply the boiler throughout the periods when the maximum output is required. The upper part of this storage vessel is always in free communication with the steam space of the boiler, and from the lower part of it the feed-water may be run into the boiler when required. The feed-water is delivered into the upper part of the vessel, and arrangements are made by which before it falls to the bottom of the chamber it runs over very extended surfaces exposed to the steam, its temperature being thus raised to that of the steam. At times when less than the normal supply of steam is required for the engine more than the average quantity of feed-water is pumped into the chamber, and the excess accumulates with its temperature raised to the evaporation point. When an extra supply of steam is required, the feed-pump is stopped and the boiler is fed with the hot water stored in the chamber. Besides the “storage” effect, it is found that many of the impurities of the feed become deposited in the chamber, where they are comparatively harmless and from which they are readily removable.

|

| Longitudinal section. |

|

| Section at AB—Front elevation. |

| Fig. 17.—Bobcock & Wilcox Water-tube Boiler (marine type). |

Oil Separators.—When the steam from the engines is condensed and used as feed-water, as is the case with marine boilers, much difficulty is often experienced with the oil which passes over with the steam. Feed-filters are employed to stop the coarser particles of the oil, but some of the oil becomes “emulsified” or suspended in the water in such extremely minute particles that they pass through the finest filtering materials. On the evaporation of the water in the boiler, this oil is left as a thin film upon the heating surfaces, and by preventing the actual contact of water with the plates has been the cause of serious trouble. An attempt has been made to overcome the emulsion difficulty by uniformly mixing with the water a small quantity of solution of lime. On the water being raised in temperature the lime is precipitated, and the minute particles separated apparently attract the small globules of oil and become aggregated in sufficient size to deposit themselves in quiet parts of the boiler, whence they can be occasionally removed either by blowing out or by cleaning. Much, however, still remains to be done before the oil difficulty will be thoroughly removed.

Corrosion.—When chemicals of any kind are used to soften or purify feed-water it is essential that neither they nor the products they form should have a corrosive effect upon the boiler-plates, &c. Much of the corrosion which occasionally occurs has been traced to the action of the oxygen of the air which enters the boiler in solution in the feed-water, and the best practice now provides for the delivery of the feed into the boiler at such positions that the air evolved from it as it becomes heated passes direct to the steam space without having an opportunity of becoming disengaged upon the under-water surfaces of the boiler.

Where corrosion is feared it is usual to fit zinc slabs in the water spaces of the boiler. Experience shows that it is better to make them of rolled rather than of cast zinc, and to secure them on studs which can be kept bright, so as to ensure a direct metallic contact between the zinc and the boiler-plate. The function of the zinc is to set up galvanic action; it plays the part of the negative metal, and is dissolved while the metal of the shell is kept electro-positive. Care must always be taken that the fragments which break off the zinc as it wastes away cannot fall upon the heating surfaces of the boiler.

|

| Fig. 18.—Handhole Fittings. |

Evaporators.—In marine boilers the waste of water which occurs from leakages in the cycle of the evaporation in the boiler, use in the engine, condensation in the condenser and return to the boiler as feed-water, is made up by fresh water distilled from sea-water in “evaporators.” Of these there are many forms with different provisions for cleaning the coils, but they are all identical in principle. They are fed with sea-water, and means are provided for blowing out the brine produced in them when some of the water is evaporated. The heat required for the evaporation is obtained from live steam from the boilers, which is admitted into coils of copper pipe. The water condensed in these coils is returned direct to the feed-water, and the steam evaporated from the sea-water is led either into the low-pressure receiver of the steam-engine or into the condenser.

Efficiency of Boilers.—The useful work obtained from any boiler depends upon many considerations. For a high efficiency, that is, a large amount of steam produced in proportion to the amount of fuel consumed, different conditions have to be fulfilled from those required where a large output of steam from a given plant is of more importance than economy of fuel. For a high efficiency, completeness of combustion of fuel must be combined with sufficient heating surface to absorb so much of the heat produced as will reduce the temperature of the funnel gases to nearly that of steam. Completeness of combustion can only be obtained by admitting considerably more air to the fire than is theoretically necessary fully to oxidize the combustible portions of the fuel, and by providing sufficient time and opportunity for a thorough mixture of the air and furnace gases to take place before the temperature is lowered to that critical point below which combustion will not take place. It is generally considered that the amount of excess air required is nearly equal to that theoretically necessary; experience, however, tends to show that much less than this is really required if proper means are provided for ensuring an early complete mixture of the gases. Different means are needed to effect this with different kinds of coal, those necessary for properly burning Welsh coal being altogether unsuitable for use with North Country or Scottish coal. As all the excess air has to be raised to the same temperature as that of the really burnt gases, it follows that an excess of air passing through the fire lowers the temperature in the fire and flues, and therefore lessens the heat transmission; and as it leaves the boiler at a high temperature it carries off some of the heat produced. A reduction of the amount of air, therefore, may, by increasing the fire temperature and lessening the chimney waste, actually increase the efficiency even if at the same time it is accompanied by a slight incompleteness of combustion.

|

| Fig. 19.—Normand Boiler. |

Mechanical Stoking.—Most boilers are hand-fired, a system involving much labour and frequent openings of the furnace doors, whereby large quantities of cold air are admitted above the fires. Many systems of mechanical stoking have been tried, but none has been found free from objections. That most usually employed is known as the “chain-grate” stoker. In this system, which is illustrated in fig. 13 (Woodeson boiler), the grate consists of a wide endless chain formed of short cast-iron bars; this passes over suitable drums at the front and back of the boiler, by the slow rotation of which the grate travels very slowly from front to back. The coal, which is broken small, is fed from a hopper over the whole width of the grate, the thickness of the fire being regulated by a door which can be raised or lowered as desired. Thus the volatile portions of the coal are distilled at the front of the fire, and pass over the incandescent fuel at the back end. The speed of travel is so regulated that by the time the remaining parts of the fuel reach the back end the combustion is nearly complete. It will be seen that the fire becomes thinner towards the back, and too much air is prevented from entering the thin portion by means of vanes actuated from the front of the boiler.

Draught.—In most boilers the draught necessary for combustion is “natural,” i.e. produced by a chimney. For marine purposes, although “natural” draught is the more common, many boiler installations are fitted with “forced” draught arrangements. Two distinct systems are used. In that known as the “closed stokehold” the stokehold compartment of the vessel is so closed that the only exit for air from it is through the fires. Air is driven into the stokehold by means of fans which are made so that they can maintain an air pressure in the stokehold above that of the outside atmosphere. This is the system almost universally adopted in war vessels, and it is used also in some fast passenger ships. The air pressure usually adopted in large vessels is that corresponding to a height of from 1 to 1½ in. of water, whilst so much as 4 in. is sometimes used in torpedo-boats and similar craft. This is, of course, in addition to the chimney-draught due to the height of the funnel. In the closed ashpit or Howden system, the stokehold is open, and fans drive the air round a number of tubes, situated in the uptake, through which the products of combustion pass on their way to the chimney. The air thus becomes heated, and part of it is then delivered into the ashpit below the fire and part into a casing round the furnace front from which it enters the furnace above the fire. In locomotive boilers the draught is produced by the blast or the exhaust steam. With natural draught a combustion of about 15 to 20 ℔ of coal per sq. ft. of grate area per hour can be obtained. With forced draught much greater rates can be maintained, ranging from 20 ℔ to 35 ℔ in the larger vessels with a moderate air pressure, to as much as 70 and even 80 ℔ per sq. ft. in the express types of boiler used in torpedo boats and similar craft.

Performance of Boilers.—The makers of several types of boilers have published particulars regarding the efficiency of the boilers they construct, but naturally these results have been obtained under the most favourable circumstances which may not always represent the conditions of ordinary working. The following table of actual results of marine boiler trials, made at the instance of the British admiralty, is particularly useful because the trials were made with great care under working conditions, the whole of the coal being weighed and the feed-water measured throughout the trials by skilled observers. The various trials can be compared amongst themselves as South Welsh coal of excellent quality was used in all cases.

In experimental tests such as those above referred to, many conditions have to be taken into account, the principal being the duration of the trial. It is essential that the condition of the boiler at the conclusion of the test should be precisely the same as at the commencement, both as regards the quantity of unconsumed coals on the fire-grate and the quantity of water and the steam-pressure in the boiler. The longer the period over which the observations are taken the less is the influence of errors in the estimation of these particulars. Further, in order properly to represent working conditions, the rate of combustion of the fuel throughout the trial must be the same as that intended to be used in ordinary working, and the duration of the test must be sufficient to include proportionately as much cleaning of fires as would occur under the normal working conditions. The tests should always be made with the kind of coal intended to be generally used, and the records should include a test of the calorific value of a sample of the fuel carefully selected so as fairly to represent the bulk of the coal used during the trial. The periodic records taken are the weights of the fuel used and of the ashes, &c., produced, the temperature and quantity of the feed-water, the steam pressure maintained, and the wetness of the steam produced. This last should be ascertained from samples taken from the steam pipe at a position where the full pressure is maintained. In order to reduce to a common standard observations taken under different conditions of feed temperatures and steam pressures, the results are calculated to an equivalent evaporation at the atmospheric pressure from a feed temperature of 212° F.

Trials of Various Types of Marine Boilers

| Description of Boiler. | Grate Area sq. ft. |

Heating Surface sq. ft. |

Duration of Trial Hours. |

Coal burned Per sq. ft. of Grate per Hour. |

Air Pressure in Stoke- hold— Inches of Water. |

Chimney Draught— Inches of Water |

Water Evaporated per ℔ of Coal. |

Water Evapor- ated per sq. ft. of Heating Surface. |

Thermal Units per ℔ of coal. |

Effic- iency of Boiler %. |

|

| Actual | From and at 212° F. |

||||||||||

| ℔ | ℔ | ℔ | |||||||||

| Ordinary cylindrical single- ended; 3 furnaces; 155 ℔ working pressure; closed stokehold system.* |

81 | 2308 | 25 | 14.2 | Nil | 0.36 | 8.56 | 10.26 | 4.26 | 14,267 | 69.7 |

| ” | ” | 24 | 13.9 | ” | 0.50 | 8.84 | 10.33 | 4.32 | 14,697 | 68.0 | |

| ” | ” | 9 | 30.3 | 0.81 | 0.39 | 7.93 | 9.27 | 8.46 | 14,686 | 61.4 | |

| ” | ” | 8½ | 29.1 | 0.65 | 0.32 | 8.84 | 10.34 | 9.05 | 14,612 | 68.4 | |

| Ordinary cylindrical single- ended; 3 furnaces; 210 ℔ working pressure; closed ashpit, Howden system.** |

63.2 | 2876 in boiler, 766 in air heaters |

13 | 20.6 | In Ash- pit 1.53 |

0.58 | 11.30 | 12.33 | 5.14 | 14,475 | 82.3 |

| Niclausse water-tube; 160 ℔ working pressure. |

46 | 1322 | 8 | 12.8 | Nil | 0.20 | 8.41 | 10.15 | 3.75 | 14,680 | 66.9 |

| ” | ” | 8 | 21.9 | ” | 0.20 | 8.01 | 9.40 | 6.11 | 14,760 | 62.1 | |

| ” | ” | 37 | 20.2 | ” | 0.29 | 7.62 | 9.00 | 5.44 | 14,600 | 60.5 | |

| Niclausse water-tube; 250 ℔ working pressure. |

34 | 990 | 9 | 14.0 | 0.10 | 0.23 | 8.77 | 10.50 | 4.17 | 14,640 | 69.8 |

| ” | ” | 9 | 22.0 | 0.27 | 0.23 | 7.68 | 9.06 | 5.74 | 14,640 | 60.4 | |

| ” | ” | 90 | 15.4 | Nil | Not asce- rtained |

7.61 | 9.08 | 4.00 | 14,630 | 59.9 | |

| Babcock water-tube; 33⁄16 in. tubes; 260 ℔ working pressure. |

36 | 1010 | 9 | 13.0 | ” | 0.26 | 9.31 | 11.02 | 4.30 | 14,590 | 73.2 |

| ” | ” | 9 | 20.0 | 0.18 | 0.20 | 8.58 | 10.11 | 6.13 | 14,590 | 67.0 | |

| ” | ” | 90 | 14.5 | Nil | Not asce- rtained |

8.09 | 9.53 | 4.18 | · · | 63.1 | |

| Babcock water-tube; 113⁄16 in. tubes; 270 ℔ working pressure.*** |

62 | 2167 | 28 | 18.4 | ” | 0.45 | 8.94 | 10.61 | 4.61 | 14,520 | 70.7 |

| ” | ” | 24 | 19.2 | ” | 0.47 | 8.93 | 10.59 | 4.82 | 14,390 | 71.1 | |

| ” | ” | 12 | 20.5 | ” | 0.42 | 9.42 | 11.04 | 5.41 | 14,080 | 75.8 | |

| ” | ” | 7 | 28.9 | 0.50 | Not asce- rtained |

8.54 | 9.88 | 6.91 | 14,390 | 66.3 | |

| ” | ” | 30 | 19.9 | Nil | 0.38 | 10.11 | 12.00 | 6.01 | 14,530 | 79.9 | |

| ” | ” | 29 | 27.1 | 0.66 | 0.23 | 9.96 | 11.67 | 8.05 | 14,630 | 77.1 | |

| Belleville water-tube with economizers; 320 ℔ working pressure. |

44 | 910 in boiler; | 24½ | 15.8 | Nil | 0.36 | 9.65 | 11.46 | 4.94 | 14,697 | 77.2 |

| ” | 447 in econo- | 24 | 17.4 | ” | 0.39 | 9.33 | 11.00 | 5.30 | 14,805 | 71.8 | |

| ” | mizer; | 11 | 19.8 | ” | 0.43 | 9.39 | 11.03 | 6.38 | 14,578 | 73.3 | |

| ” | 1357 total. | 8 | 27.2 | ” | 0.39 | 8.28 | 9.79 | 7.78 | 14,611 | 65.0 | |

| Yarrow water tube; 1¾ in. tubes; 250 ℔ working pressure. |

56 | 2896 | 26 | 16.9 | Nil | 0.31 | 9.57 | 11.45 | 3.12 | 14,750 | 75.0 |

| ” | ” | 26 | 18.2 | ” | 0.31 | 9.37 | 11.33 | 3.30 | 14,500 | 75.7 | |

| ” | ” | 25 | 21.3 | ” | 0.31 | 8.83 | 10.45 | 3.63 | 13,500 | 75.2 | |

| ” | ” | 30 | 35.4 | 0.53 | 0.26 | 8.82 | 10.59 | 6.04 | 14,430 | 70.9 | |

| ” | ” | 8 | 41.9 | 0.86 | 0.31 | 8.24 | 9.94 | 6.69 | 14,500 | 66.3 | |

| ” | ” | 8 | 33.7 | 0.31 | 0.30 | 8.39 | 9.93 | 5.47 | 14,680 | 65.4 | |

| ” | ” | 8 | 39.8 | 0.82 | 0.24 | 8.85 | 10.43 | 6.81 | 14,530 | 69.5 | |

| Dürr water-tube; 250 ℔ working pressure. |

71 | 2671 in boiler, 140 in super- heater; 2811 total. |

26 | 16.1 | Nil | 0.39 | 7.95 | 9.50 | 3.24 | 14,500 | 63.8 |

| ” | 26 | 17.7 | ” | 0.30 | 7.06 | 9.28 | 3.43 | 14,620 | 61.7 | ||

| ” | 25 | 21.1 | ” | 0.31 | 7.62 | 9.08 | 4.05 | 14,650 | 60.3 | ||

| ” | 7 | 33.8 | 0.70 | 0.36 | 7.72 | 9.29 | 6.59 | 14,570 | 62.7 | ||

| ” | 8 | 26.7 | 0.33 | 0.35 | 7.86 | 9.26 | 5.30 | 14,320 | 63.1 | ||

| ” | 8 | 34.6 | 1.11 | 0.20 | 8.02 | 9.53 | 7.02 | 14,230 | 64.8 | ||

| ” | 22 | 34.8 | 0.73 | 0.16 | 6.84 | 8.06 | 6.02 | 14,430 | 54.0 | ||

| ” | 24 | 29.9 | 0.35 | 0.12 | 7.62 | 9.00 | 5.75 | 14,240 | 61.2 | ||

| ” | 20 | 19.9 | Nil | 0.21 | 7.30 | 8.33 | 3.66 | 14,240 | 8.6 | ||

| * In the first three trials no retarders were used in the tubes. In the last trial retarders were used. | |||||||||||

| ** In this trial retarders were used in the tubes. | |||||||||||

| *** The first four trials were made with horizontal baffles above the tubes; the last two trials with the baffling described in the text. | |||||||||||

Boiler Making

The practice of the boiler, bridge and girder shops may here be conveniently treated together, because similar materials and methods are employed in each, notwithstanding that many points of divergence in practice generally relegate them to separate departments. The materials used are chiefly iron and steel. The methods mostly adopted are those involved in the working of plates and rolled sections, which vastly predominate over the bars and rods used chiefly in the smithy. But there are numerous differences in methods of construction. Flanging occupies a large place in boilermaking, for end-plates, tube-plates, furnace flues, &c., but is scarcely represented in bridge and girder work. Plates are bent to cylindrical shapes in boilermaking, for shells and furnaces, but not in girder work. Welding is much more common in the first than in the second, furnace flues being always welded and stand pipes frequently. In boiler work holes are generally drilled through the seams of adjacent plates. In bridge work each plate or bar is usually drilled or punched apart from its fellows. Boilers, again, being subject to high temperatures and pressures, must be constructed with provisions to ensure some elasticity and freedom of movement under varying temperatures to prevent fractures or grooving, and must be made of materials that combine high ductility with strength when heated to furnace temperatures. Flanging of certain parts, judicious staying, limitation of the length of the tubes, the forms of which are inherently weak, provide for the first; the selection of steel or iron of high percentage elongation, and the imposition of temper, or bending tests, both hot and cold, provide for the second.

The following are the leading features of present-day methods.

It might be hastily supposed that, because plates, angles, tees, channels and joist sections are rolled ready for use, little work could be left for the plater and boilermaker. But actually so much is involved that subdivisions of tasks are numerous; the operations of templet-making, rolling, planing, punching and shearing, bending, welding and forging, flanging, drilling, riveting, caulking, and tubing require the labours of several groups of machine attendants, and of gangs of unskilled labourers or helpers. Some operations also have to be done at a red or white heat, others cold. To the first belong flanging and welding, to the latter generally all the other operations. Heating is necessary for the rolling of tubes of small diameter; bending is done cold or hot according to circumstances.

|

| Fig. 20.—Thornycroft-Schulz Water-tube Boiler. |

The fact that some kinds of treatment, as shearing and punching, flanging and bending, are of a very violent character explains why practice has changed radically in regard to the method of performing these operations in cases where safety is a cardinal matter. Shearing and punching are both severely detrusive operations performed on cold metal; both leave jagged edges and, as experience has proved, very minute cracks, the tendency of which is to extend under subsequent stress, with liability to produce fracture. But it has been found that, when a shorn edge is planed and a punched hole enlarged by reamering, no harm results, provided not less than about 1⁄16 in. is removed. A great advance was therefore made when specifications first insisted on the removal of the rough edges before the parts were united.

In the work of riveting another evil long existed. When holes are punched it is practically impossible to ensure the exact coincidence of holes in different plates which have to be brought together for the purpose of riveting. From this followed the use of the drift,—a tapered rod driven forcibly by hammer blows through corresponding holes in adjacent plates, by which violent treatment the holes were forcibly drawn into alignment. This drifting stressed the plates, setting up permanent strains and enlarging incipient cracks, and many boiler explosions have been clearly traceable to the abuse of this tool. Then, next, specifications insisted that all holes should be enlarged by reamering after the plates were in place. But even that did not prove a safeguard, because it often happened that the metal reamered was nearly all removed from one side of a hole, so leaving the other side just as the punch had torn it. Ultimately came the era of drilling rivet-holes, to which there is no exception now in high-class boiler work. For average girder and bridge work the practice of punching and reamering is still in use, because the conditions of service are not so severe as are those in steam boilers.

Flanging signifies the turning or bending over of the edges of a plate to afford a means of union to other plates. Examples occur in the back end-plates of Lancashire and Cornish boilers, the front and back plates of marine boilers, the fire-boxes of locomotive boilers, the crowns of vertical boilers, the ends of conical cross-tubes, and the Adamson seams of furnace flues. This practice has superseded the older system of effecting union by means of rings forming two sides of a rectangular section (angle iron rings). These were a fruitful source of grooving and explosions in steam boilers, because their sharp angular form lacked elasticity; hence the reason for the substitution of a flange turned with a large radius, which afforded the elasticity necessary to counteract the effects of changes in temperature. In girder work where such conditions do not exist, the method of union with angles is of course retained. In the early days of flanging the process was performed in detail by a skilled workman (the angle ironsmith), and it is still so done in small establishments. A length of edge of about 10 in. or a foot is heated, and bent by hammering around the edge of a block of iron of suitable shape. Then another “heat” is taken and flanged, and another, until the work is complete. But in modern boiler shops little hand work is ever done; instead, plates 4 ft., 6 ft., or 8 ft. in diameter, and fire-box plates for locomotive boilers, have their entire flanges bent at a single squeeze between massive dies in a hydraulic press. In the case of the ends of marine boilers which are too large for such treatment, a special form of press bends the edges over in successive heats. The flanges of Adamson seams are rolled over in a special machine. A length of flue is rotated on a table, while the flange is turned over within a minute between revolving rollers. There is another advantage in the adoption of machine-flanging, besides the enormous saving of time, namely, that the material suffers far less injury than it does in hand-flanging.

These differences in practice would not have assumed such magnitude but for the introduction of mild steel in place of malleable iron. Iron suffers less from overheating and irregular heating than does steel. Steel possesses higher ductility, but it is also more liable to develop cracks if subjected to improper treatment. All this and much more is writ large in the early testing of steel, and is reflected in present-day practice.

A feature peculiar to the boiler and plating shops is the enormous number of rivet holes which have to be made, and of rivets to be inserted. These requirements are reflected in machine design. To punch or drill holes singly is too slow a process in the best practice, and so machines are made for producing many holes simultaneously. Besides this, the different sections of boilers are drilled in machines of different types, some for shells, some for furnaces, some peculiar to the shells or furnaces of one type of boilers, others to those of another type only. And generally now these machines not only drill, but can also be adjusted to drill to exact pitch, the necessity thus being avoided of marking out the holes as guides to the drills.

Hand-riveting has mostly been displaced by hydraulic and pneumatic machines, with resulting great saving in cost, and the advantage of more trustworthy and uniform results. For boiler work, machines are mostly of fixed type; for bridge and girder work they are portable, being slung from chains and provided with pressure water or compressed air by systems of flexible pipes.

Welding fills a large place in boiler work, but it is that of the edges of plates chiefly, predominating over that of the bars and rods of the smithy. The edges to be united are thin and long, so that short lengths have to be done in succession at successive “heats.” Much of this is hand work, and “gluts” or insertion pieces are generally preferred to overlapping joints. But in large shops, steam-driven power hammers are used for closing the welds. Parts that are commonly welded are the furnace flues, the conical cross-tubes and angle rings.

Another aspect of the work of these departments is the immense proportions of the modern machine tools used. This development is due in great degree to the substitution of steel for iron. The steel shell-plates of the largest boilers are 1½ in. thick, and these have to be bent into cylindrical forms. In the old days of iron boilers the capacity of rolls never exceeded about ¾ in. plate. Often, alternatively to rolling, these thick plates are bent by squeezing them in successive sections between huge blocks operated by hydraulic pressure acting on toggle levers. And other machines besides the rolls are made more massive than formerly to deal with the immense plates of modern marine boilers.

The boiler and plating shops have been affected by the general tendency to specialize manufactures. Firms have fallen into the practice of restricting their range of product, with increase in volume. The time has gone past when a single shop could turn out several classes of boilers, and undertake any bridge and girder work as well. One reason is to be found in the diminution of hand work and the growth of the machine tool. Almost every distinct operation on every section of a boiler or bridge may now be accomplished by one of several highly specialized machines. Repetitive operations are provided for thus, and by a system of templeting. If twenty or fifty similar boilers are made in a year, each plate, hole, flange or stay will be exactly like every similar one in the set. Dimensions of plates will be marked from a sample or templet plate, and holes will be marked similarly; or in many cases they are not marked at all, but pitched and drilled at once by self-acting mechanism embodied in drilling machines specially designed for one set of operations on one kind of plate. Hundreds of bracing bars for bridges and girders will be cut off all alike, and drilled or punched from a templet bar, so that they are ready to take their place in bridge or girder without any adjustments or fitting.